Slope Monitoring of Open-Pit Mines

In China, open-pit mining accounts for a large proportion of mining activities. With the continuous development and utilization of shallow mineral resources, the depth of mining operations has been increasing, leading to more steep and high slopes with decreasing stability. The stability of mine slopes has always been a major concern in open-pit mining operations. On August 30, 2023, the National Mine Safety Supervision Bureau issued a notice regarding the construction and networking of open-pit mine slope monitoring systems. The plan aims to complete the construction of a national open-pit mine safety production risk monitoring and early warning system within three years. This system will enable the identification, monitoring, and precise assessment of major safety risks in key areas and critical processes of open-pit mines. Monitoring of surface slope deformation and slope video images is deemed necessary, with internal deformation, stress, blast vibrations, rainfall, groundwater, and other factors as additional monitoring items.

Tailings Reservoir Monitoring

A tailings reservoir refers to a site formed by damming a valley mouth or enclosing an area, used for storing tailings discharged after ore beneficiation in metal or non-metal mines or other industrial waste residues. It is a man-made debris flow hazard with high potential energy, facing the risk of dam failure. Once a failure occurs, it is likely to cause major or extraordinarily serious accidents.The main causes of tailings reservoir dam failure include seepage failure, flood overtopping, slope instability, and seismic liquefaction. The primary reasons for seepage failure and overtopping failure are insufficient freeboard, excessively short dry beach length, excessively high phreatic line, and excessive rainfall. The main causes of tailings reservoir dam instability and failure are overly steep slopes, tensile stress at the slope top, and shear stress at the slope toe.

Based on the analysis of the causes of tailings reservoir dam failure, the main monitoring contents are determined as follows: dam surface displacement, deep horizontal displacement, dam cracks, reservoir water level, dry beach length, phreatic line, rainfall intensity, and video monitoring.

▋Monitoring Project for Slopes of Iron Mine Pit and Dumping Site in Panzhihua City, Sichuan Province

For the slope monitoring project of an iron ore stope and waste dump in Panzhihua City, Sichuan Province, the mining area of the mine is 1.6139 km², with a mining depth ranging from 1880 m to 1550 m. The mine's production capacity was increased from 1.5 million tons/year to 8 million tons/year in 2012. The mine has three waste dumps, and the annual rock stripping volume of the stope is approximately 10 million tons.

To ensure the safe production of the mine, after on-site investigation, an automated monitoring project was implemented for the East Stope, West Stope, and No.1 Waste Dump of the mine. The project adopted the intelligent vision gauge system to conduct surface displacement monitoring on the following targets: Zhujiayakou No.1 Gully Waste Dump, Yingpanshan Slope of the West Stope, North Slope of the West Stope, North Slope of the East Stope, and Fault No.65 Slope of the East Stope. A total of 12 survey lines were laid along the slope platform, with a monitoring range of 250 meters per line and measuring points spaced 50 meters apart. 1 intelligent vision gauge was used for each survey line, involving a total of 12 intelligent vision gauges and 60 reflective targets.

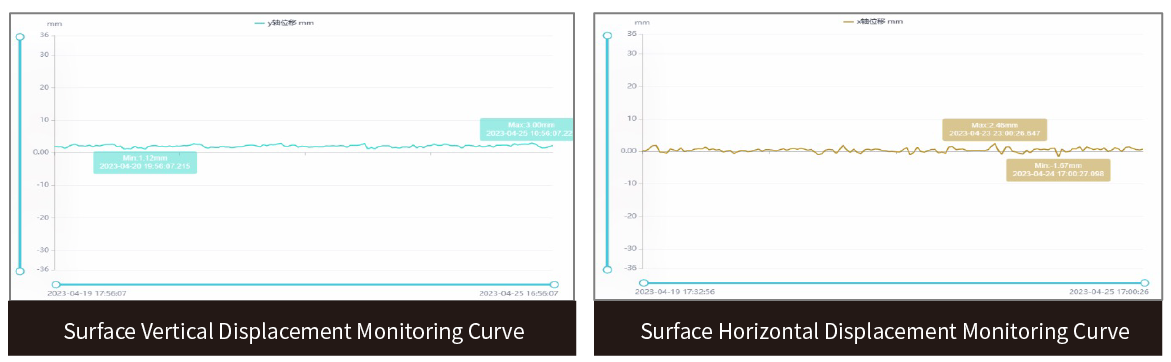

Since the monitoring system was installed, the equipment has operated stably. The fluctuation values of the surface vertical and horizontal displacements of the mine slope are within 5 mm, and no divergence phenomenon has occurred in the cumulative deformation. The mine is generally in a healthy state, with no obvious excessive deformation.

▋Monitoring Project for a Tailings Pond in Liangshan Prefecture, Sichuan Province

After the initial dam of this tailings pond was cleared, the surface elevation was 1573.0m, and the top of the dam was at an elevation of 1640.0m, with an initial dam height of 67.0m and an initial effective storage capacity of 135.05x104m4. The axis length of the dam is 210.8m. The final top elevation of the piled dam is 1726.0m, with a piled dam height of 86m. There are currently 24 stacked subsidiary dams, with their top elevations at 1688.0m, making it a third-class tailings pond.

The monitoring content of the project mainly includes surface displacement, internal displacement, infiltration line, dry beach, reservoir water level, rainfall, etc. Monitoring is carried out using equipment such as intelligent vision gauges, in-place inclinometers, piezometers, and rain gauges, with project data transmitted in real-time to a third-party management platform.

© Toehold Engineering Technology Co., Ltd.Shanghai