A wind turbine is a large electromechanical device that converts wind energy into mechanical energy and then into electrical energy. A single wind turbine unit includes blades, a turbine, a tower, and a foundation. To achieve maximum energy output efficiency, offshore wind farms need to be established in offshore areas and operated with unmanned management. Consequently, the structure of the wind turbines is directly exposed to variable and even extreme climatic conditions, making them highly susceptible to the impacts of typhoons, tropical cyclones, earthquakes, waves, lightning, and blizzards.

The primary causes of offshore wind turbine failures can be divided into two categories: one is damage caused by the repeated action of dynamic and static loads, and the other is damage caused by foundation instability.

Load-induced damage: For offshore wind turbines, the combined effects of strong typhoons and waves are significant factors that cannot be ignored in the monitoring of wind turbine structures. Many regions in China are prone to frequent earthquakes, making seismic loads a concern for both onshore and offshore wind farms to ensure their stable operation. Excessive loads can cause buckling damage to the tower and blades.

Foundation instability damage: Factors such as seabed geological conditions, design plans, and construction techniques can cause uneven settlement or excessive settlement of the wind turbine foundation. The fast-rotating wind turbine shaft has particularly stringent requirements for foundation settlement, and the settlement must be controlled within permissible limits to ensure the normal operation of the wind turbine equipment.

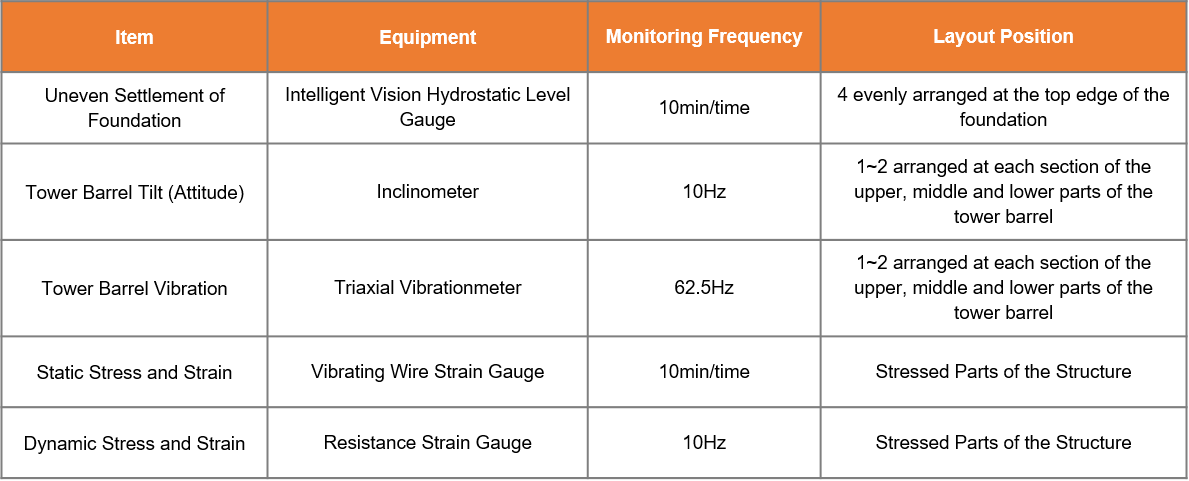

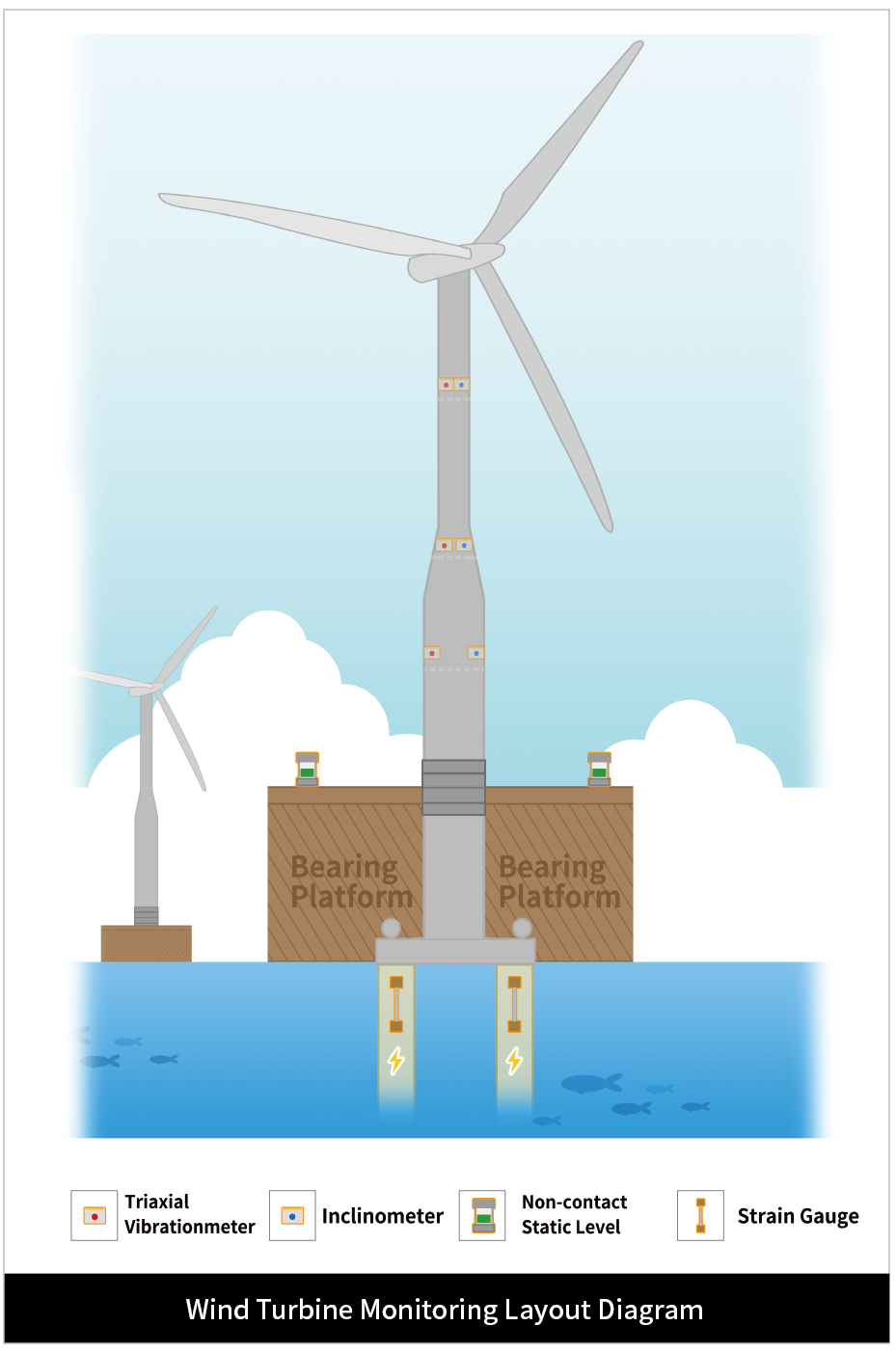

The main equipment for monitoring offshore wind turbines includes hydrostatic leveling gauges, inclinometers, triaxial accelerometers, and strain gauges.

▋A Offshore Wind Power Monitoring Project in Jiaxing City, Zhejiang Province

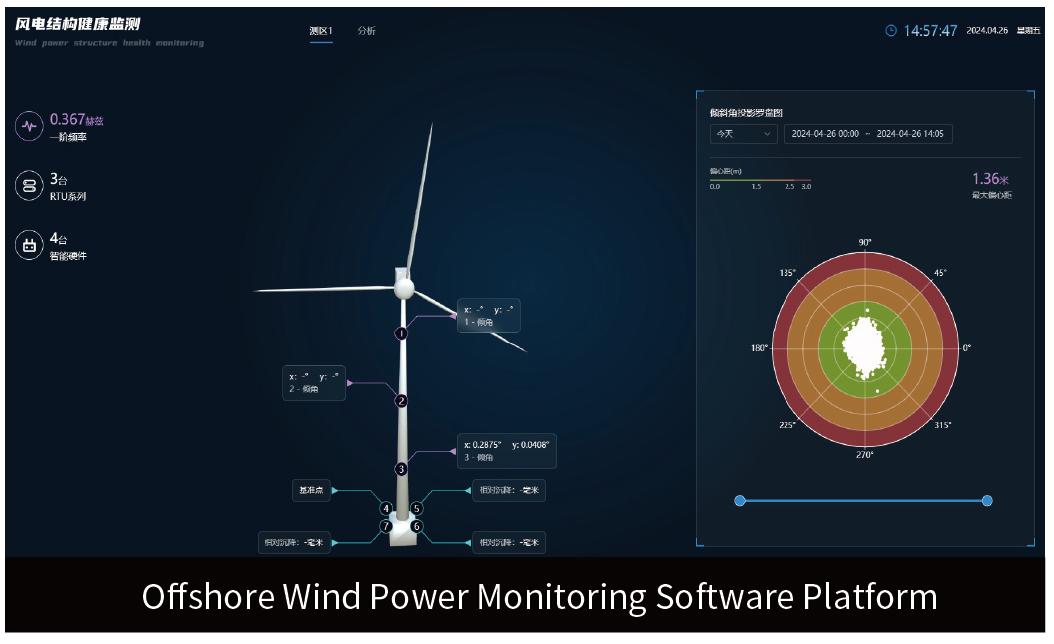

This offshore wind power project has an installed capacity of 300MW, consisting of 75 wind turbine units with a single-unit capacity of 4MW, 155km of submarine cables, and a 220kV offshore booster station. The project includes real-time inclination monitoring of the No. 37 wind turbine tower. Six triaxial accelerometers and three data acquisition devices (RTU) have been installed. The collected acceleration data is transmitted via 4G signal to the TOEHOLD Sensing Cloud Data Management Platform, where the monitoring data is analyzed to provide data support for the operation and management of the wind power project.

▋A Offshore Wind Power Monitoring Project in Nantong, Jiangsu Province, China

This offshore wind farm is located in the offshore area of Rudong County, Jiangsu Province, approximately 25 kilometers away from the shore. The seabed elevations range from -3.7 meters to -15.3 meters. To ensure the safe operation of wind turbines and the substation, automated safety monitoring is implemented for 2 wind turbines and 1 offshore substation within the wind farm.

In this project, ttriaxial vibrationmeters are used to monitor the vibration acceleration and inclination angle of the wind turbines and the offshore substation. These testers can synchronously output high-frequency vibration and inclination angle data. For the wind turbine structure, one triaxial vibrationmeter is installed at the top of the wind turbine pile; for the offshore substation, two triaxial vibrationmeters are adopted, which are respectively installed on the columns at both ends of the diagonal of the first-floor deck level of the substation.

Since the monitoring system was installed and put into operation, the monitoring data has remained stable. No sudden or continuous inclination, nor significant vibration has occurred in the structure. The wind turbines and the substation have been in a stable state.

© Toehold Engineering Technology Co., Ltd.Shanghai