The prestressing tensioning program-control system consists of a program-control host unit and an operation front-end. The operation front-end includes: measurement and control circuits, an oil pump, hydraulic jacks, sensors, and other components. The D-Type is the flagship system, which utilizes a dual-circuit numerically controlled oil pump capable of simultaneously driving four hydraulic jacks to achieve symmetrical tensioning of two steel strands.

The host unit comprises an industrial panel computer and a dedicated program-controlled software system, capable of monitoring and controlling multiple numerically controlled oil pumps via wireless signals. Following preset tensioning procedures and corresponding parameters, the host unit directs the operation of one or more numerically controlled oil pumps. It continuously calculates control commands based on monitoring data fed back from these pumps, enabling precise and ongoing regulation.

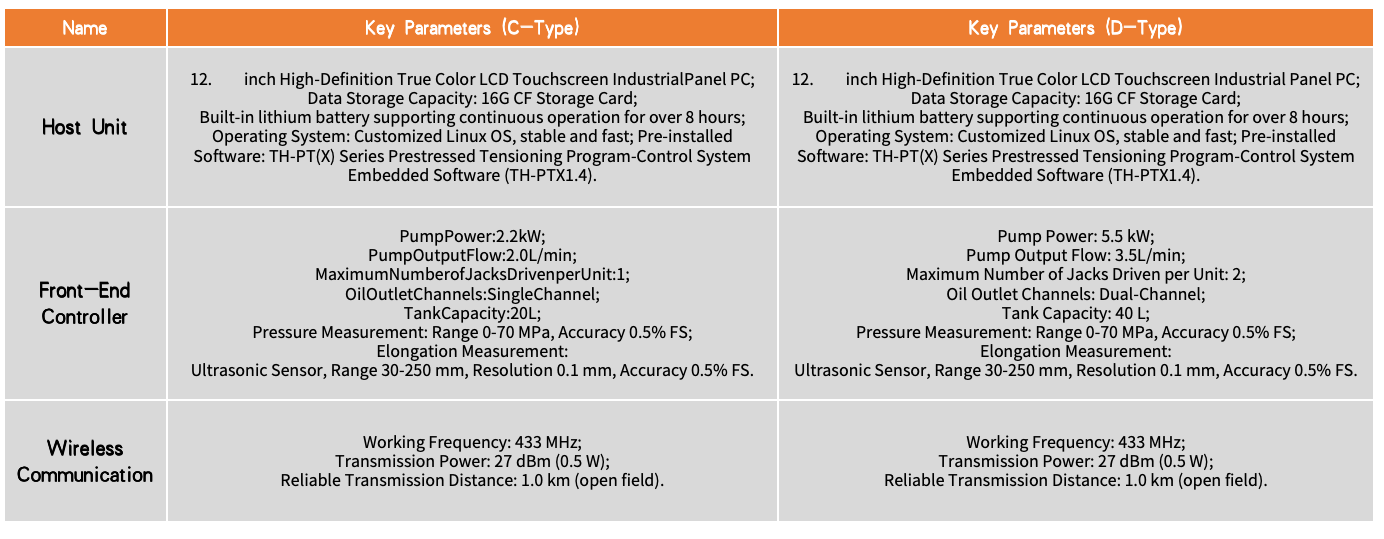

The numerically controlled oil pumps monitor key data points such as the jack's working tension and the elongation (or retraction) of the steel strands. This data is transmitted in real-time to the host unit, which subsequently sends back control commands. Based on these instructions, the pumps dynamically adjust the inverter's operating parameters. This allows for highly precise real-time regulation of the oil pump motor's speed, ensuring accurate control over the tensioning force and loading rate.

The D-Type represents the fully automatic flagship model. Utilizing two oil pumps, it can simultaneously drive four jacks, enabling the concurrent tensioning of two steel strands. The entire process is executed through one-touch operation, automatically completing the full prestressing tensioning procedure for both strands.

© Toehold Engineering Technology Co., Ltd.Shanghai