This system is a fully automated digital control system designed for load testing of large-scale structural components, such as shield tunnel segments and bridge members.

The system operates through the integrated functioning of a control center, intelligent hydraulic stations, and precision sensors to meet the testing requirements for designed loads. It simulates various working conditions for testing, allows on-demand load regulation, and enables real-time monitoring of structural displacement and stress changes. This ensures highly unified and synchronized data acquisition, which facilitates data analysis and design verification. While ensuring safe and precise control, the system automatically records all test data throughout the entire process and simultaneously uploads it to a cloud platform. This allows for retrospective review of the entire test status via the test data at any time.

The system requires no manual intervention and offers a high degree of intelligence, significantly improving work efficiency. Furthermore, it incorporates multiple safety redundancies and alarm mechanisms. The system automatically halts operation upon triggering an alarm and prompts for manual intervention, ensuring safety.

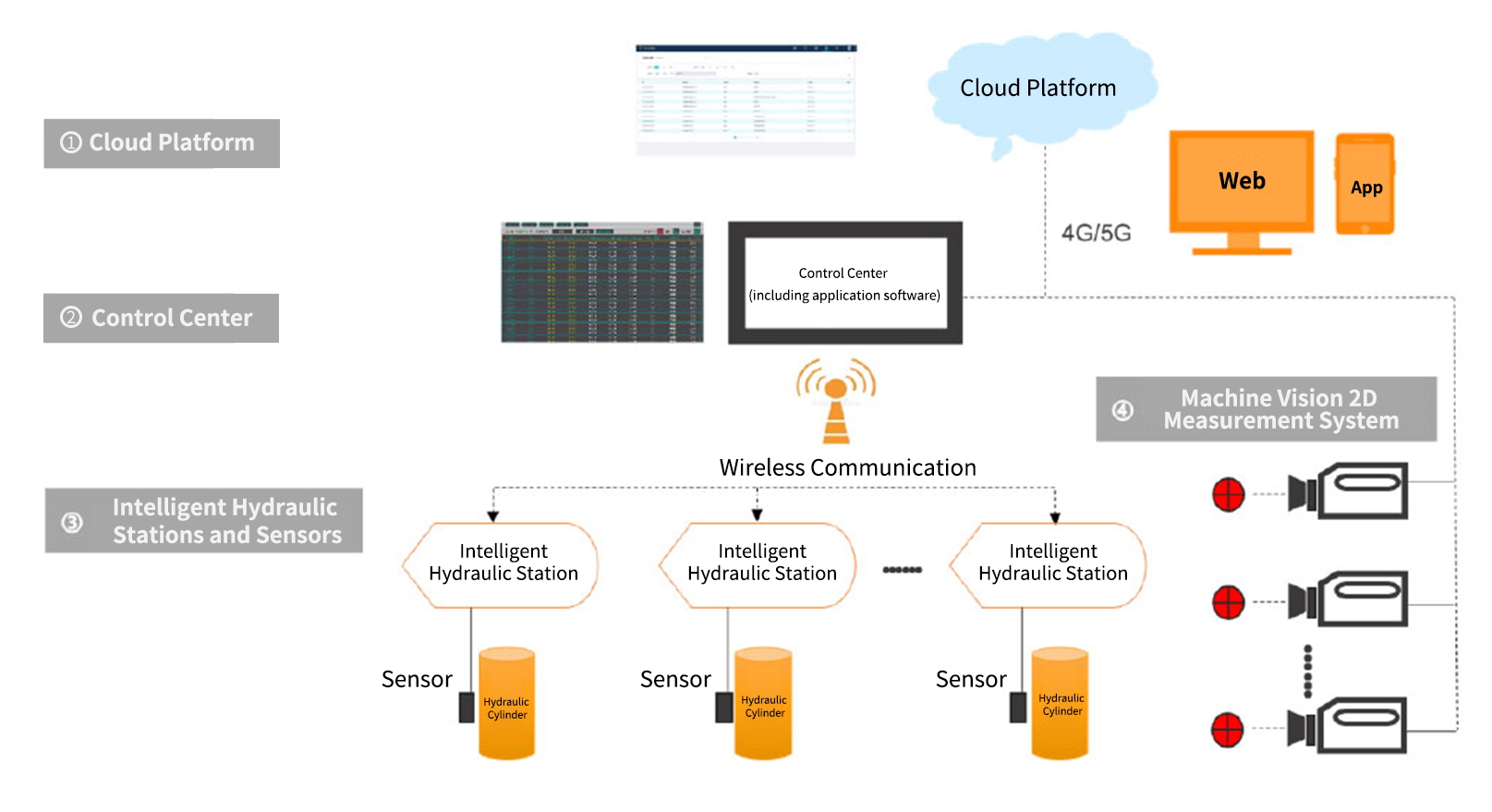

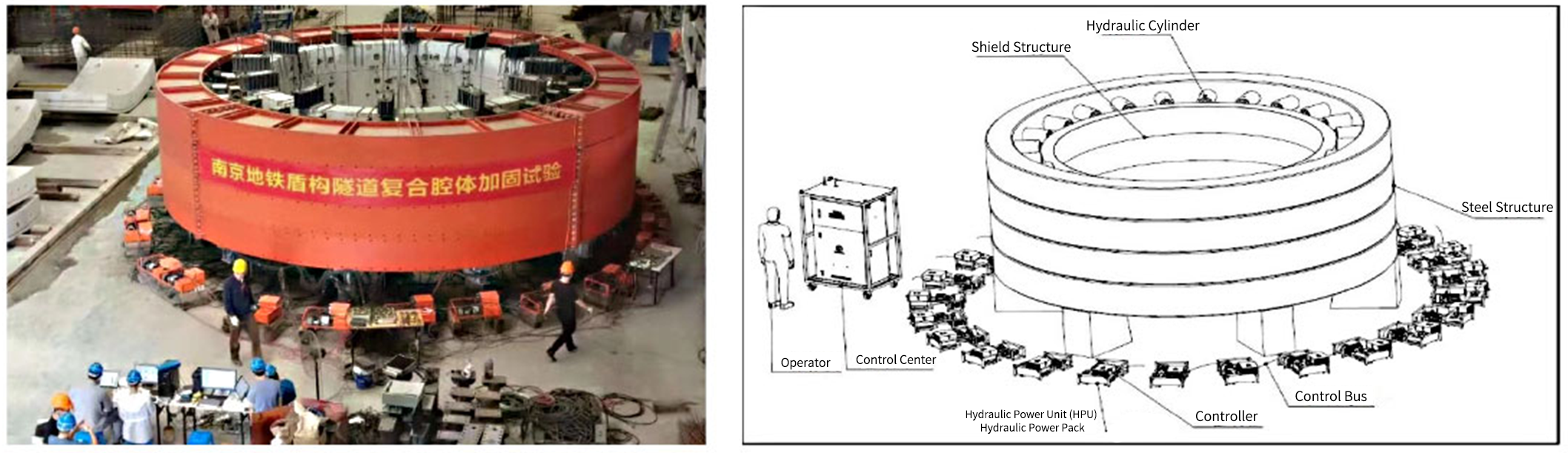

The system primarily consists of a cloud platform, a control center, intelligent hydraulic stations, hydraulic cylinders, sensors, and a machine vision measurement system. The quantities of intelligent hydraulic stations, hydraulic cylinders, sensors, and machine vision measurement systems can be flexibly configured according to the test design requirements.

The control center, equipped with built-in master control software, is responsible for converting test configurations into hydraulic control targets and distributing them to the intelligent hydraulic stations. The embedded controllers within the hydraulic stations operate at a millisecond-level response rate, performing autonomous control based on the received targets and driving the hydraulic cylinders to execute loading actions. Simultaneously, the various sensors and the machine vision measurement system within the system monitor minute deformations on the component in real-time, feeding the data back to the interface to support intelligent decision-making by both the system and human operators.

All test data is automatically uploaded to the cloud platform via the network throughout the entire process. This enables long-term unattended load testing. Users can view and manage test data at any time through a web browser or dedicated application (APP).

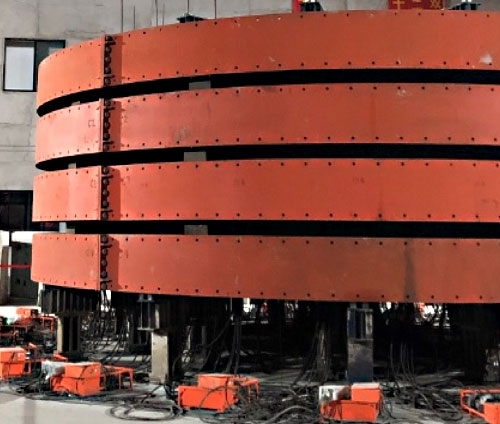

▋ Full-Scale Loading Test on an Ultra-Deep Buried Shield Tunnel Segment at a Hangzhou Metro Project

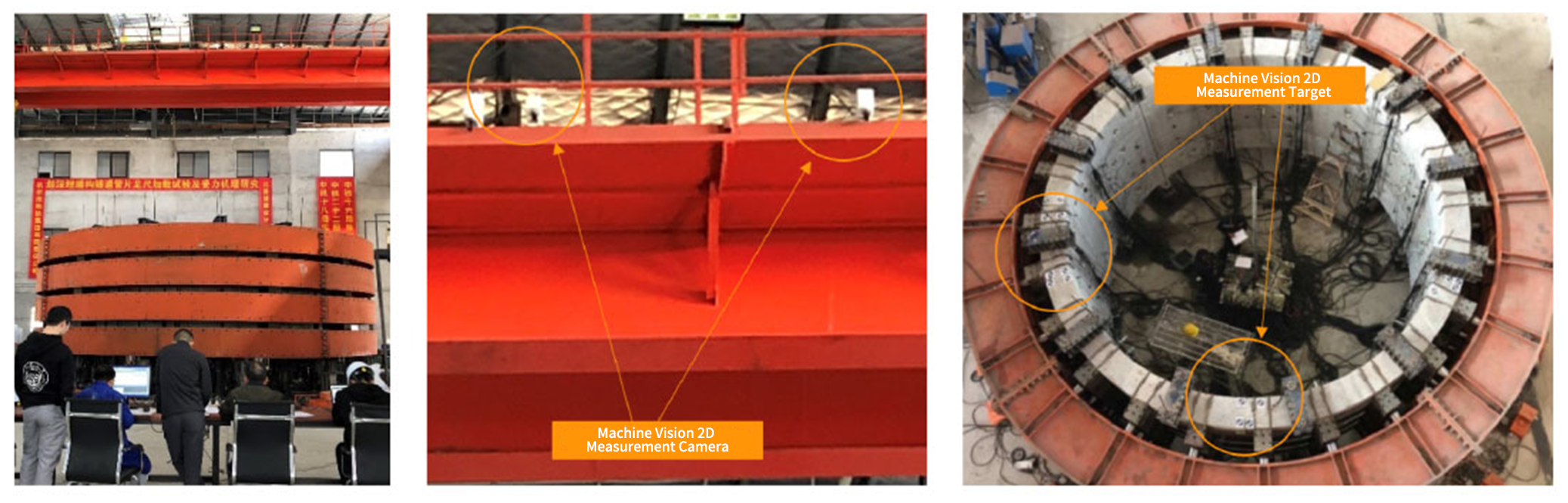

A full-ring structural test was conducted, utilizing 1 control center, 24 intelligent hydraulic stations, and 3 machine vision 2D measurement systems. The test successfully completed the required multi-condition loading and load-holding phases, assessing force and deformation. It measured displacement changes at up to 20 specified measuring points on the structure and successfully simulated the structural convergence deformation state. The test verified that the actual load-bearing capacity of the structure met the design requirements.

▋Composite Cavity Reinforcement Test on a Shield Tunnel at a Nanjing Metro Project

Utilizing 1 control center paired with 24 intelligent hydraulic stations, the test achieved 24-point synchronous control. The system maintained continuous loading for one month, successfully simulating various composite working conditions and satisfactorily fulfilling all test design requirements.

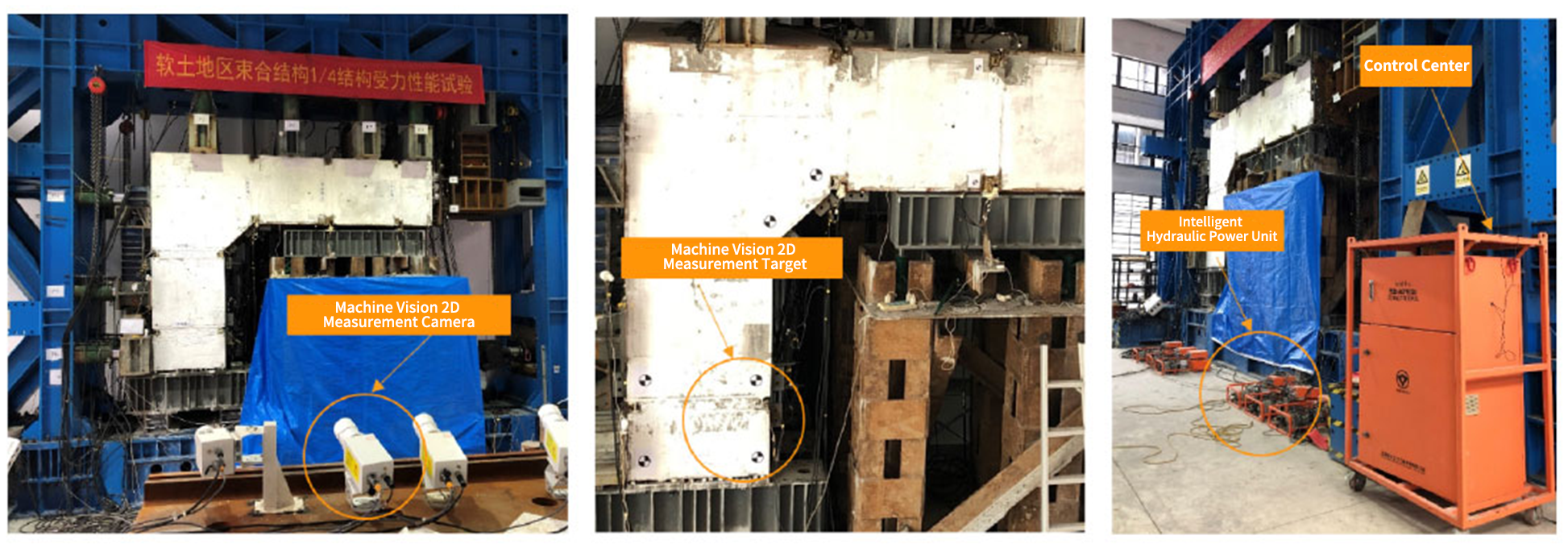

▋Structural Performance Test on a 1/4 Scale Model of a Shanghai Metro Station

A 1/4 scale structural test of a bundled structure in a soft soil area was conducted, utilizing 6 intelligent hydraulic stations and 4 machine vision 2D measurement systems. While successfully completing multi-condition loading and load-holding tests, the system also measured displacement changes at 23 designated measuring points on the structure via the machine vision measurement systems, effectively simulating the structural convergence deformation state.

© Toehold Engineering Technology Co., Ltd.Shanghai