Prestressed tensioning is a critical construction methodology applied before concrete pouring, involving the pre-tensioning of steel reinforcement to optimize stress distribution within reinforced concrete structures during their service life. Stress measurement in prestressed steel reinforcement serves as a vital indicator of construction quality and constitutes an essential inspection item specified in highway and bridge construction codes.

The prestressed tensioning solution comprises a software platform and hardware system. The hardware consists of a program-controlled host unit and field operation units, including measurement and control circuitry, numerically controlled pump stations, dedicated hydraulic jacks, load sensors, and other components. The program-controlled host utilizes an industrial-grade panel computer equipped with proprietary software. The entire system operates on the re-tensioning method principle to test individual steel strands. This system has been widely deployed in Zhejiang, Yunnan, Guangdong, Guizhou, Anhui, Guangxi, and other provinces.

The product technology complies with the following national/local standards:

Industry Standard: Technical Specifications for Construction of Highway Bridges and Culverts (JTG/T F50)

Zhejiang Provincial Standard: Technical Specification for Post-Tensioned Prestressed Construction of Highway Bridges (DB33/T 2154)

Anhui Provincial Standard: Guidelines for Detection of Effective Stress in Prestressed Tensioning of Highway and Waterway Engineering (DB34/T 3177)

Chongqing Municipal Standard: Specification for Construction Quality Inspection and Acceptance of Bridge Prestressing and Cable Tensioning (CQJTG/T F81)

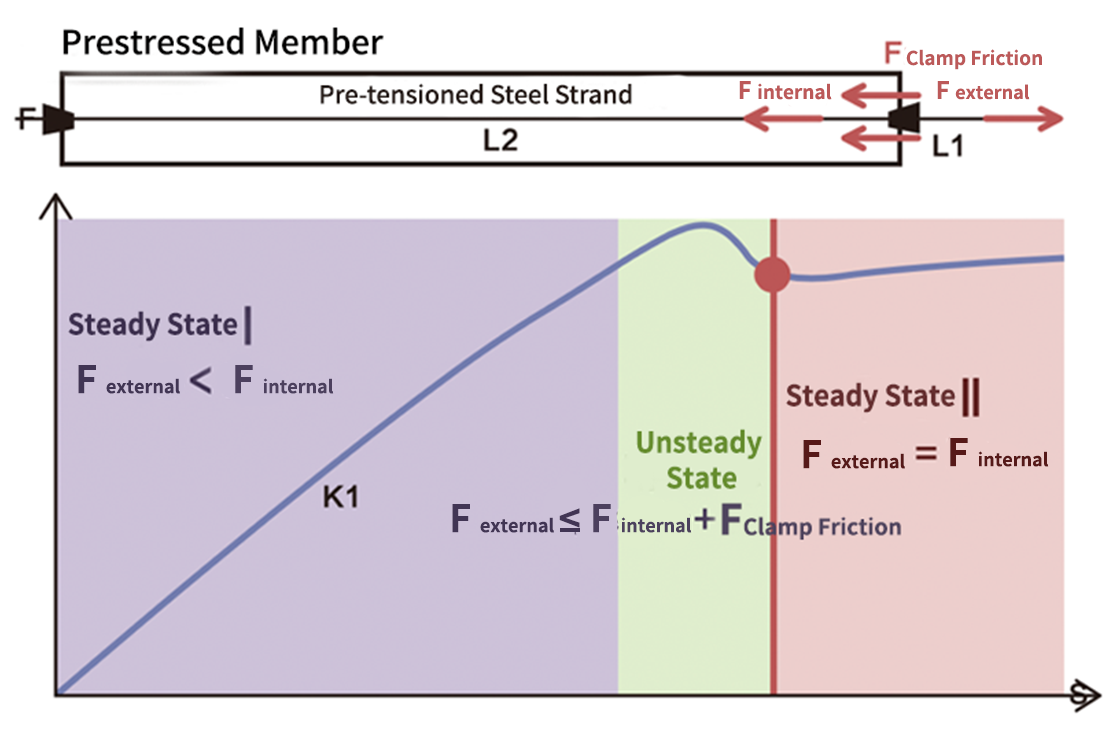

The system employs the re-tensioning method to detect the effective stress in individual steel strands. The fundamental principle of the re-tensioning method involves applying tension to a single, exposed strand while simultaneously measuring both the applied tension force and the resulting displacement of the strand.

During the re-tensioning process, the external strand undergoes a transition from a steady state to an unsteady state and then returns to a steady state. The inflection point tension force observed upon the second entry into the steady state represents the effective stress within the prestressed steel tendon.

The TH-TST Series Tension Stress Detector comprises a program-controlled computer, a portable numerically controlled pump station, and a dedicated hydraulic jack. The program-controlled computer utilizes an industrial-grade panel PC, offering high protection rating and long battery life, making it suitable for complex construction site environments. The portable numerically controlled pump station is highly integrated and easily portable, featuring a built-in battery that eliminates the need for on-site power supply. The dedicated hydraulic jack is specially designed for prestress detection, ensuring easy installation.

The program-controlled computer runs proprietary automated detection software. This software includes an interface for the Tonggan Cloud IoT service, enabling automatic upload of test results to the cloud. This facilitates remote management of multiple projects.

Detection of effective prestress deviation

Verification of tensioning equipment load control accuracy

Measurement of intra-bundle stress uniformity

Testing of anchorage friction loss

Assessment of cross-section stress distribution uniformity

Measurement of duct friction loss

We provide comprehensive technical support services for both software and hardware operations and maintenance. Our technical team consists of civil engineers, hardware engineers, and software engineers, equipped with the capability to perform customized development for both software and hardware.

© Toehold Engineering Technology Co., Ltd.Shanghai