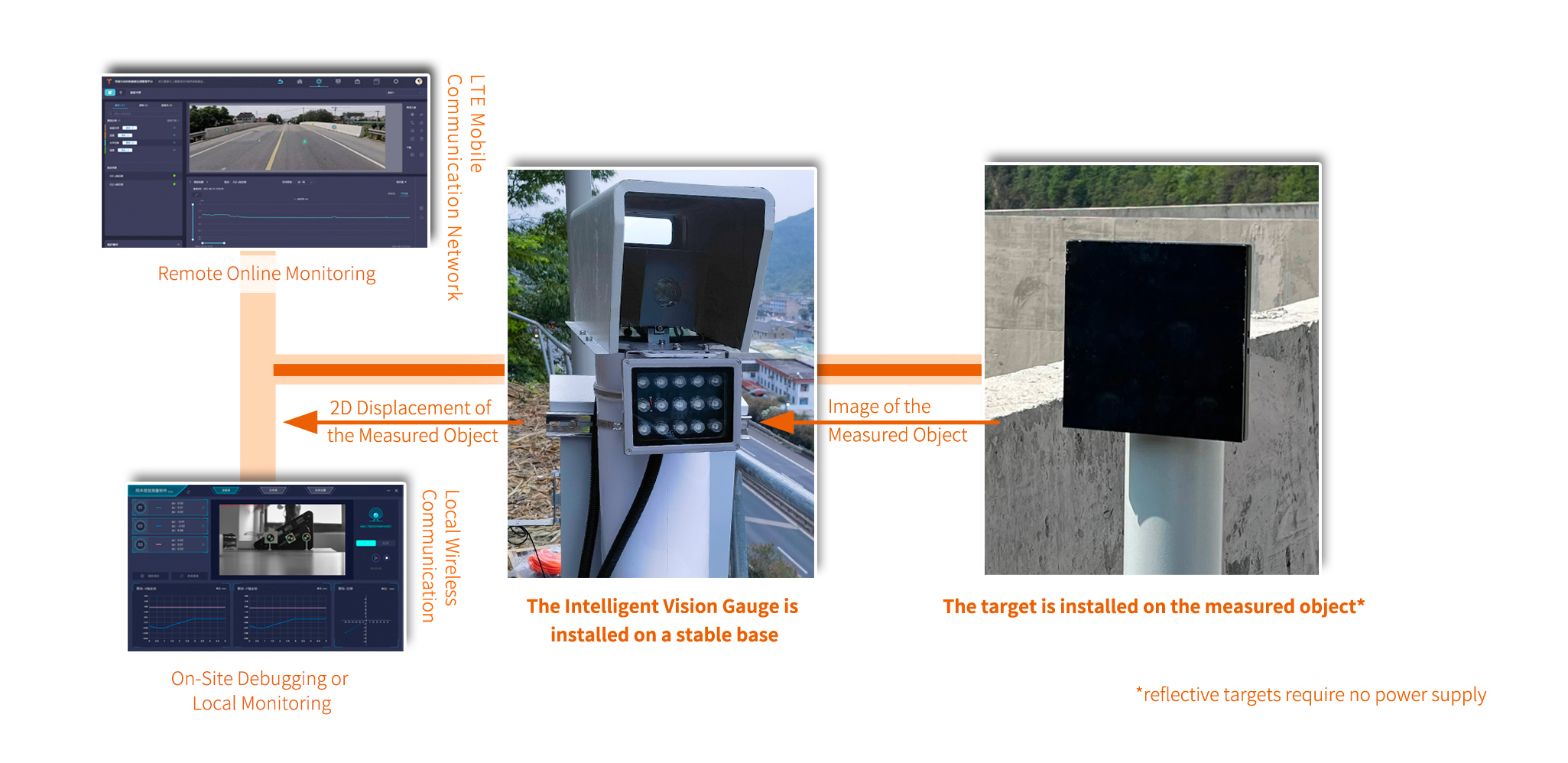

The intelligent vision gauge system uses IoT technology and intelligent disaster identification algorithms to convert image data into deformation data, achieving ultra-high precision, non-contact real-time measurements of various civil engineering structures. This enables long-term monitoring of structural health. The system consists of intelligent vision gauges, targets, on-site configuration software, and the TOEHOLD Sensing Cloud (a structural health monitoring management platform).

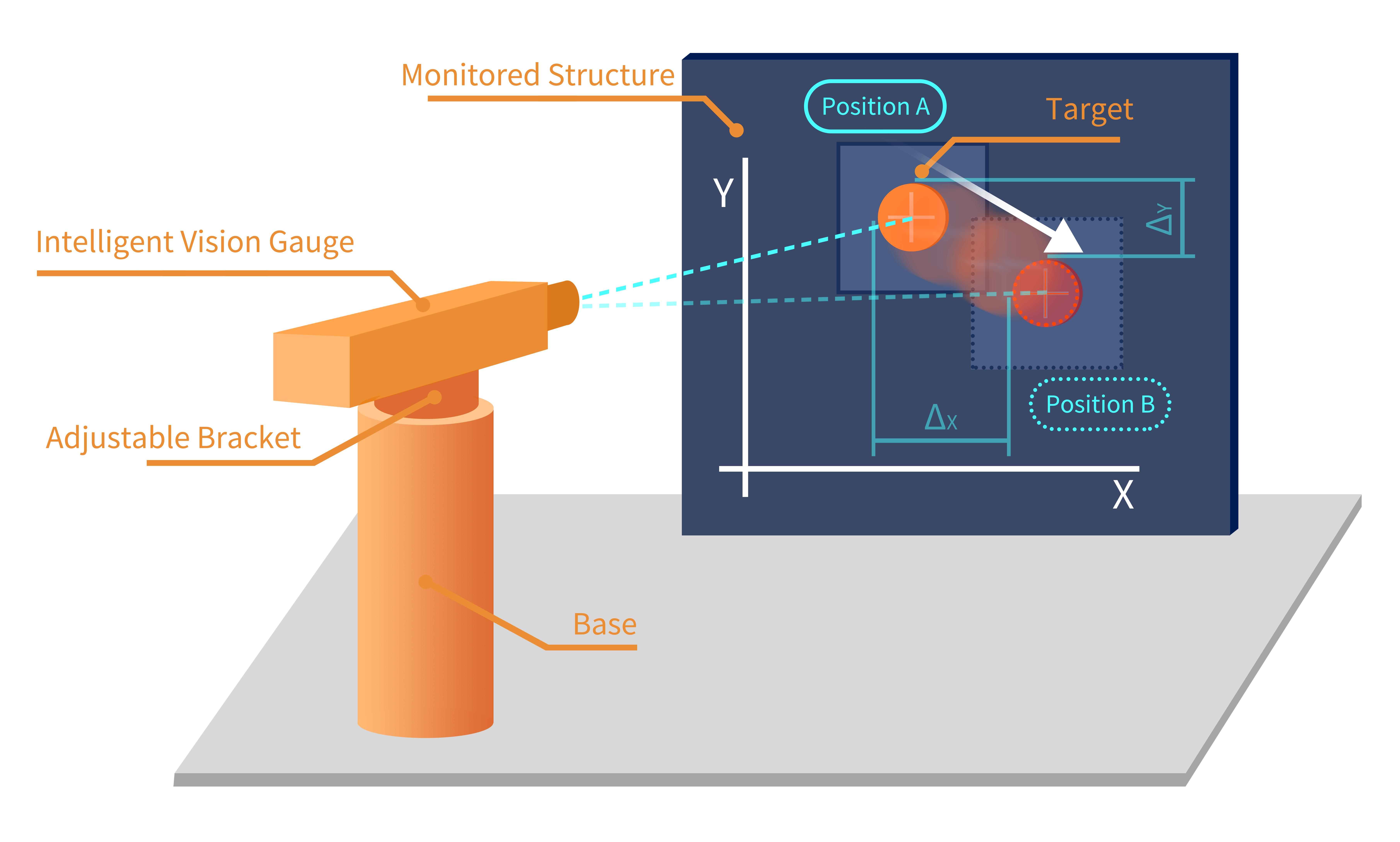

Targets are installed on the structure to be measured, and the intelligent vision gauge is installed at a stable position relative to the structure. The gauge can identify the targets on the structure, and when the structure experiences planar displacement, the coordinates of the targets change accordingly, measuring the horizontal and vertical displacements of the structure.

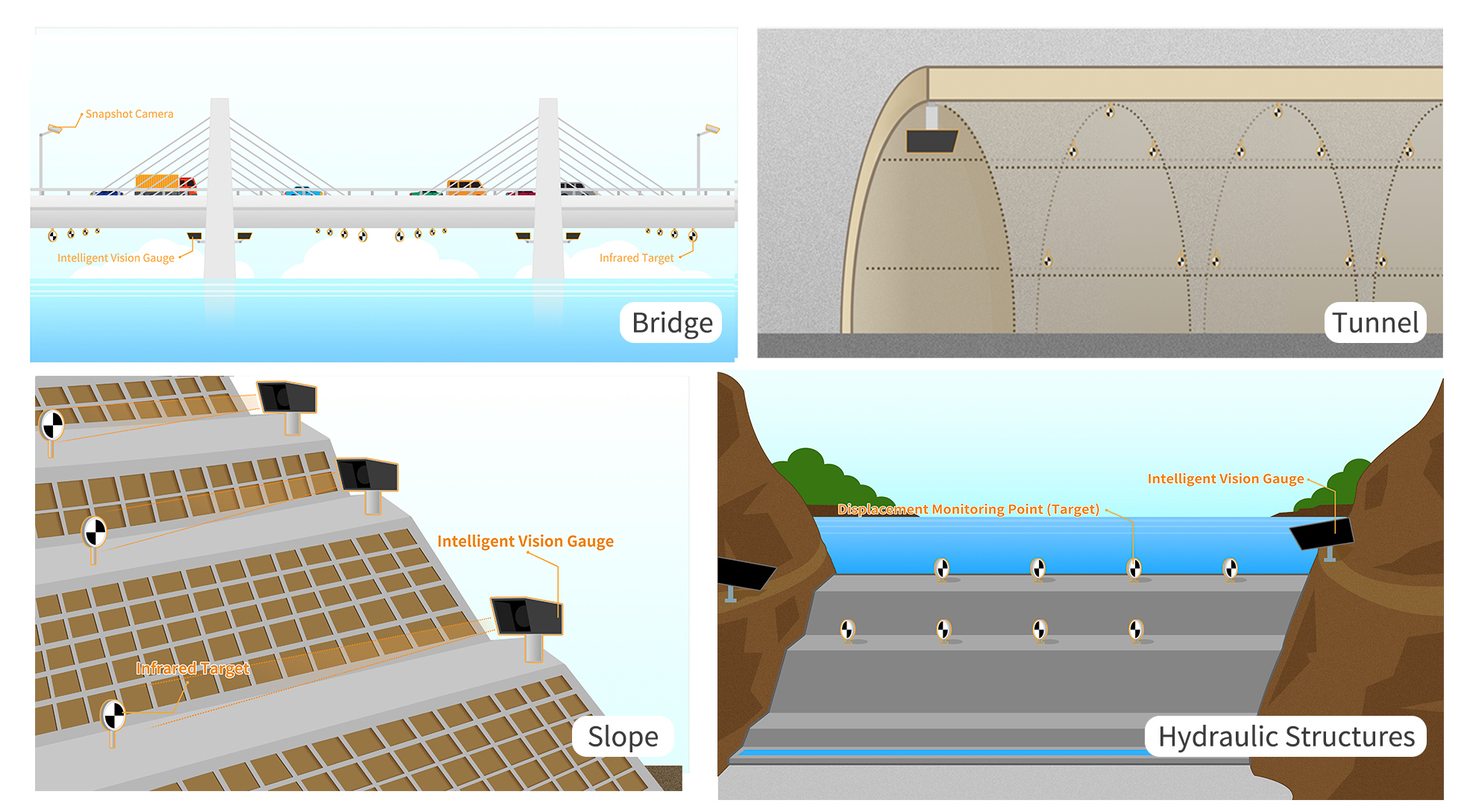

This system is widely used in two-dimensional displacement monitoring of slopes, foundation pits, dams, buildings, bridges, and other structures.

For detailed product specifications, please contact our sales team for further discussion.

The intelligent vision gauge contains an embedded computing module, which can perform distortion processing on the recorded target images, correct target displacement, and improve the monitoring accuracy of structural displacement. At the same time, it adopts a dynamic local window algorithm to solve the problems of complex operations and large computation load, thus enabling all monitoring data to be operated and computed in the local micro embedded computing module.

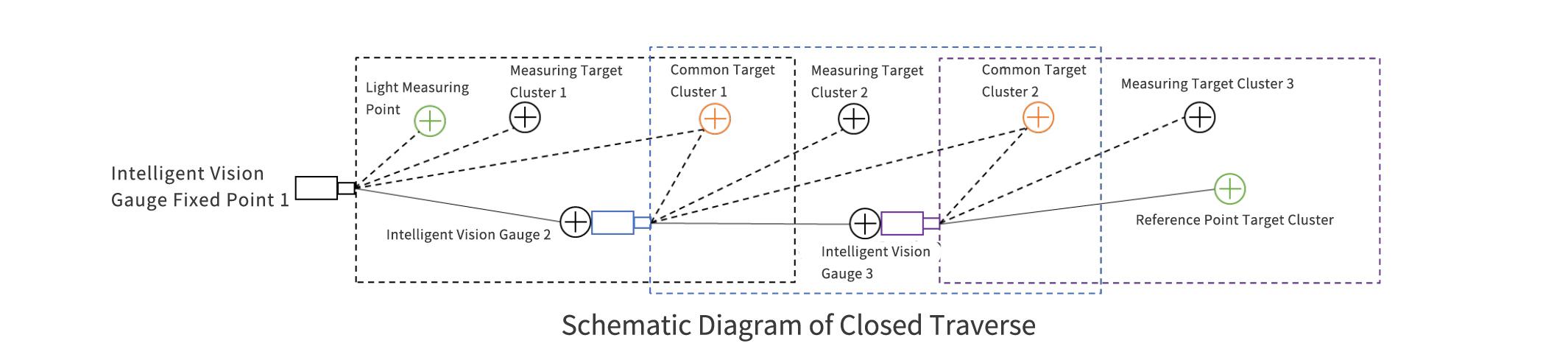

In long-distance tunnel measurement or measurement of long-distance, large-curved reservoir dams, using a single intelligent vision gauge for monitoring has a problem: the intelligent vision gauge measuring system with a single camera is limited by the field of view of image acquisition equipment, making it difficult to cover the entire range of the monitored structure. The adoption of "Intelligent Vision Transfer Measurement Technology" can solve the above problem. By means of forward transfer of multiple measuring gauges, a closed measurement traverse is formed, and combined with the transfer point calculation algorithm of measuring gauges, long-distance or curved measurement is realized.

▊ Monitoring of a Tunnel in Hangzhou City, Zhejiang Province

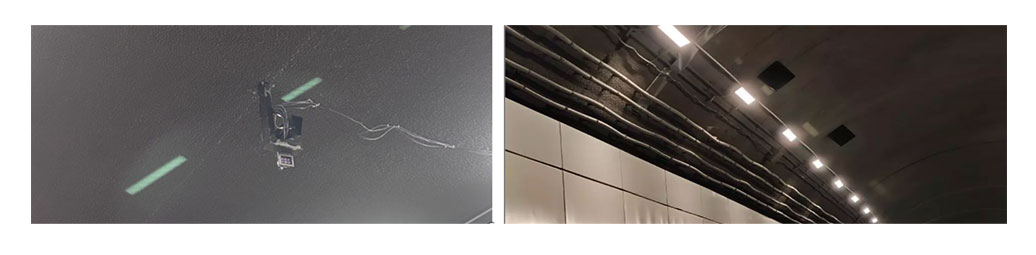

This tunnel passes through the ancient Grand Canal. Due to the impact of the adjacent Ferris wheel project and dyke project on the tunnel, it is necessary to conduct settlement and convergence monitoring on the tunnel. The construction affects a 156m section of the canal-crossing tunnel, and the monitoring scope is defined as extending at least 60m outward from each side of the construction-influenced area. For a single tunnel tube, 4 intelligent vision gauges are used for monitoring, adopting the intelligent vision gauge transfer measurement technology. Each intelligent vision gauge monitors 10 cross-sections, with 5 targets installed on each cross-section.

▊ Monitoring of a Reservoir in Ji'an City, Jiangxi Province

This is a medium-sized reservoir mainly for irrigation, with comprehensive benefits including flood control, power generation, and aquaculture. The controlled drainage area above the dam site is 17.83 km², the dam elevation is 66.2 meters, the maximum dam height is 17.3 meters, the dam crest length is 460 meters, and the dam crest width is 6 meters. Theintelligent vision gauge transfer measurement technology is adopted to monitor the surface displacement of the reservoir dam, using a total of 4 intelligent vision gauges and 14 targets (including 3 reference points).

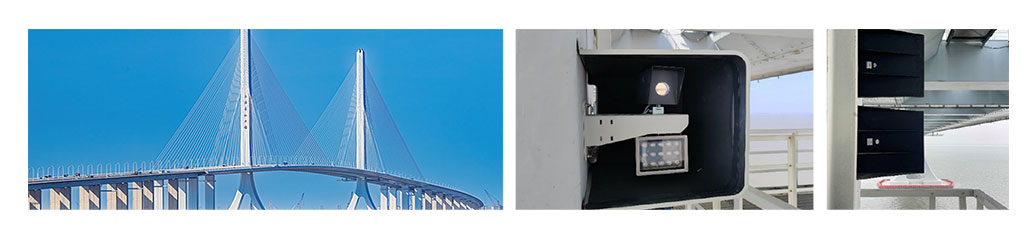

▊ Structural Health Monitoring of a Bridge in Shanghai

This bridge spans Changxing Island and Chongming Island, with the main bridge section crossing the Yangtze River measuring 9.97 km in length.

For the project, intelligent vision gauge are adopted to conduct structural health monitoring on the displacement of key bridge piers and the deflection of key box girders. A total of 13 intelligent vision gauges and 24 targets are used.

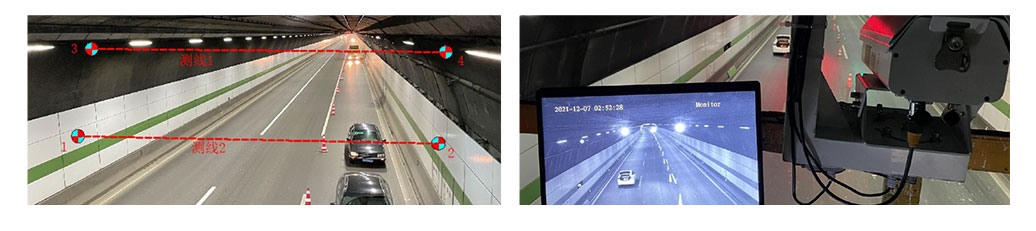

▊ Structural Health Monitoring of a River-Crossing Tunnel in Shanghai

This tunnel has an internal width of 13.7 meters and three traffic lanes.

The project uses intelligent vision gauge to conduct real-time monitoring of the tunnel structure. One measuring instrument is installed at the mid-span vault of the tunnel, and 4 targets are installed symmetrically on both sides to form two measurement lines for convergence monitoring.

▊ Slope Monitoring of an Expressway in Shaoxing City, Zhejiang Province

This expressway has a total length of approximately 231 kilometers, running through four cities in Zhejiang Province: Shaoxing, Jinhua, Taizhou, and Wenzhou. The project adopts intelligent vision gauge to simultaneously monitor the slope settlement and horizontal displacement, using a total of 11 intelligent vision gauges and 38 targets.

▊ Monitoring of Two Sluice Gates in Binzhou City, Shandong Province

The monitoring section lengths of the two sluice gates are 63.8 meters and 171 meters respectively. The project uses intelligent vision gauge to simultaneously monitor the vertical settlement and horizontal displacement of the sluice gate bodies. This project has been included in Shandong Province's List of 2022 Provincial-Level Standardized Management Water Conservancy Projects.

© Toehold Engineering Technology Co., Ltd.Shanghai