TOEHOLD Technology has developed an automation monitoring system for water conservancy structures such as dams, water gates, levees, and seawalls. This system includes displacement monitoring, seepage monitoring, rainfall forecasting, and video surveillance. By monitoring surface displacement, seepage pressure, seepage flow, rainfall, and other parameters, combined with an Internet of Things (IoT) monitoring and warning platform, the data is organized, calculated, analyzed, and presented. This enables intelligent diagnosis of the health status of water conservancy structures, providing reliable data for the management and maintenance of water infrastructure. It effectively enhances the prevention and emergency response capabilities for structural disasters in the water conservancy industry.

Surface displacement monitoring is the most important parameter for dam safety monitoring. Traditional monitoring methods include hydrostatic level gauges, total stations, GNSS, etc., but they all have issues with false alarms. After an alarm is triggered, manual verification is required at the site, leading to delays in understanding the actual situation. Using an intelligent vision gauge system to monitor surface displacement on the dam offers advantages such as real-time monitoring, high accuracy, easy installation, and low monitoring costs.

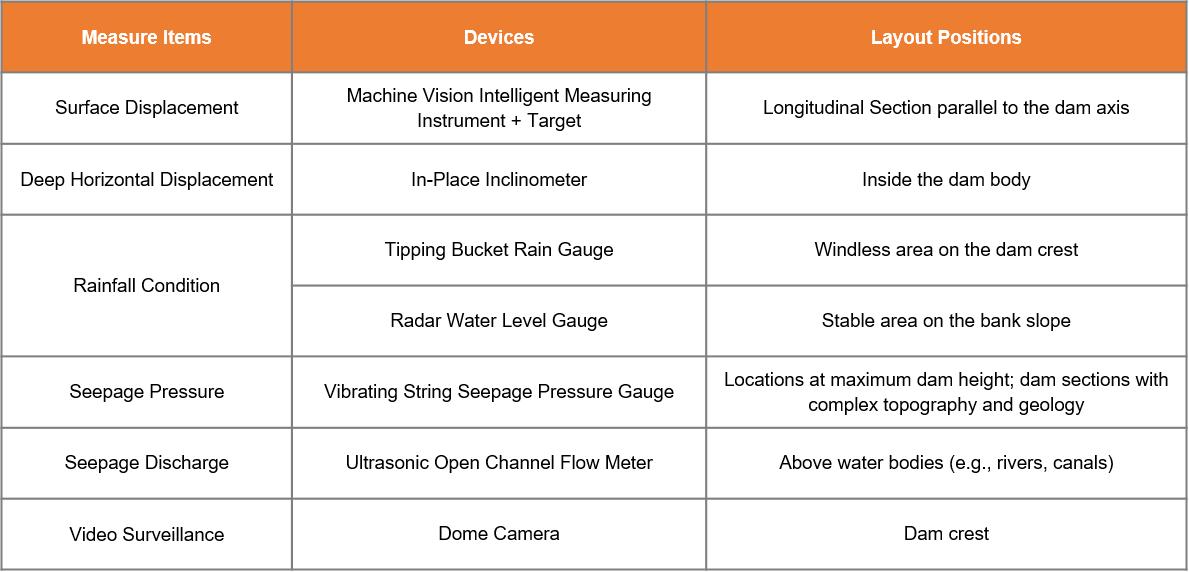

Deployment Plan

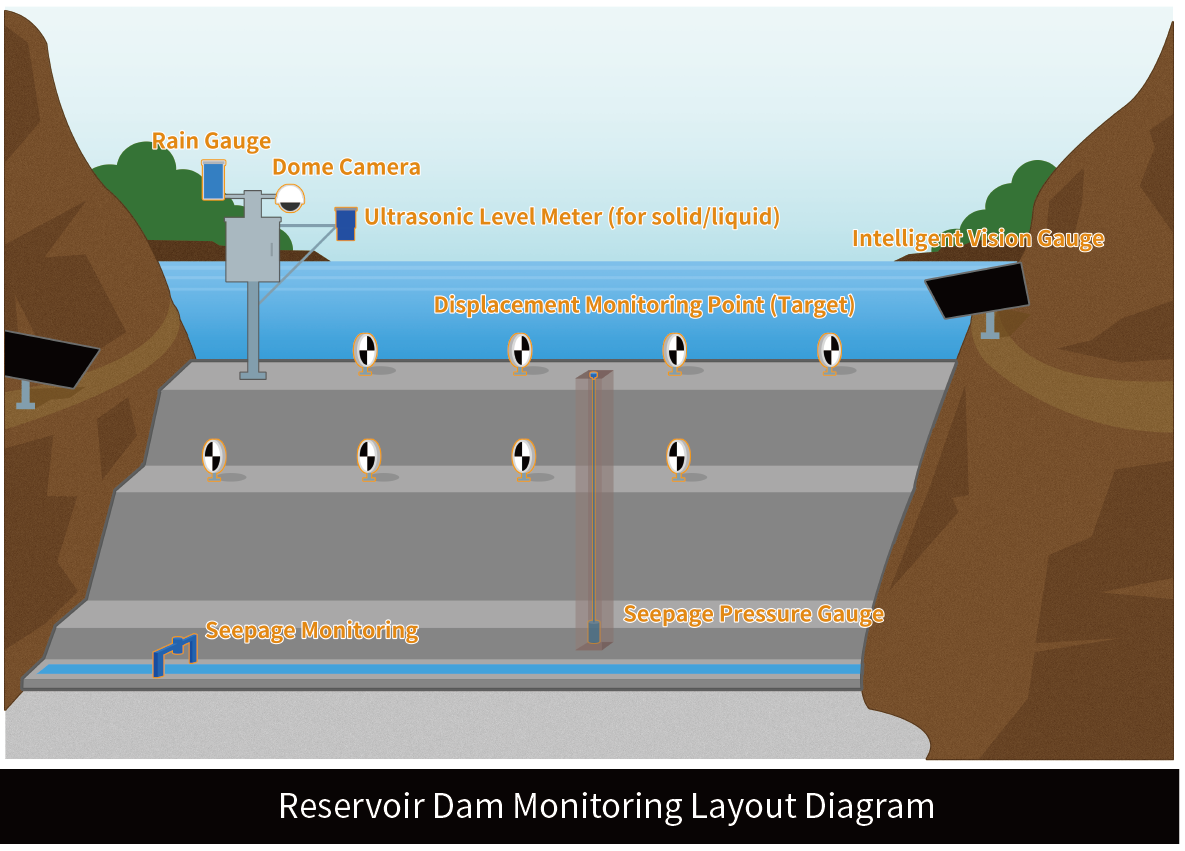

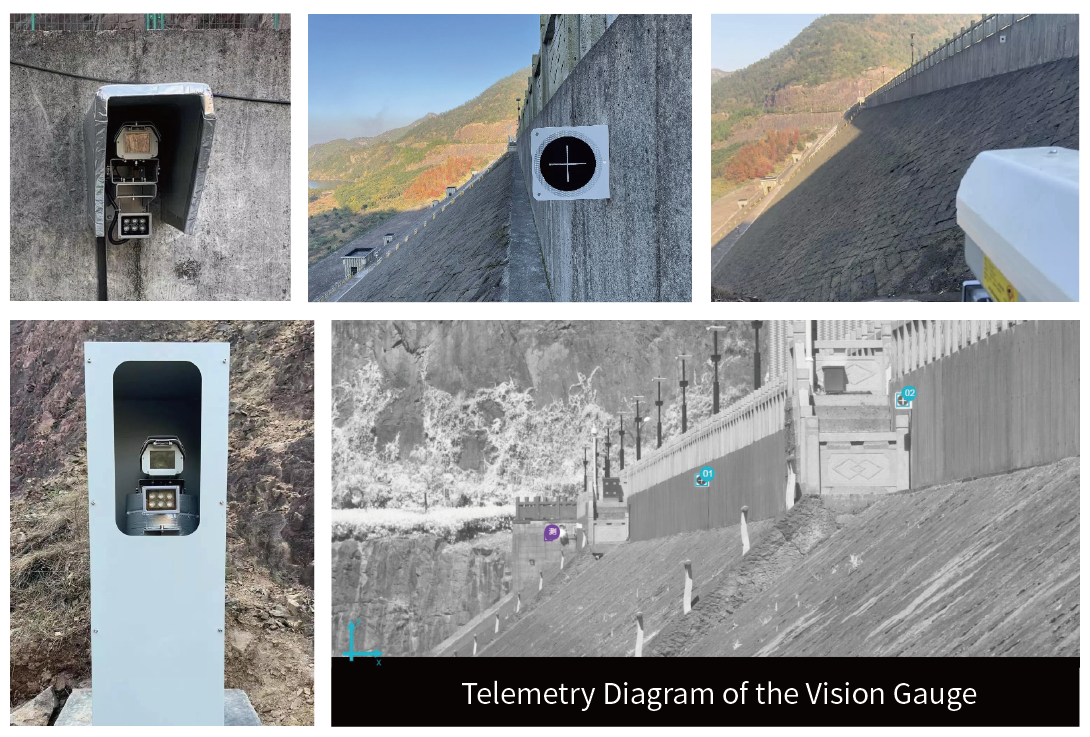

The intelligent vision gauge system is installed in stable areas on the shore, with targets placed at intervals of 20 to 50 meters on the dam crest or body. To improve monitoring accuracy, reference measurement points are added, and are generally installed in stable areas on the opposite shore.

One vision gauge can monitor multiple targets simultaneously, providing data on settlement and horizontal displacement along the river direction for each measurement point. When an alarm is received from a measurement point, video data from 1 minute before and after the alarm time is uploaded to the management platform immediately, eliminating the possibility of false alarms from true displacement incidence.

The intelligent vision gauge system can be powered by mains electricity or solar energy. The collected data can be transmitted to the TOEHOLD Sensing Cloud or other third-party platform via 4G/5G wireless transmission, wired connection, fiber optic, etc.

▋Measurement Principle

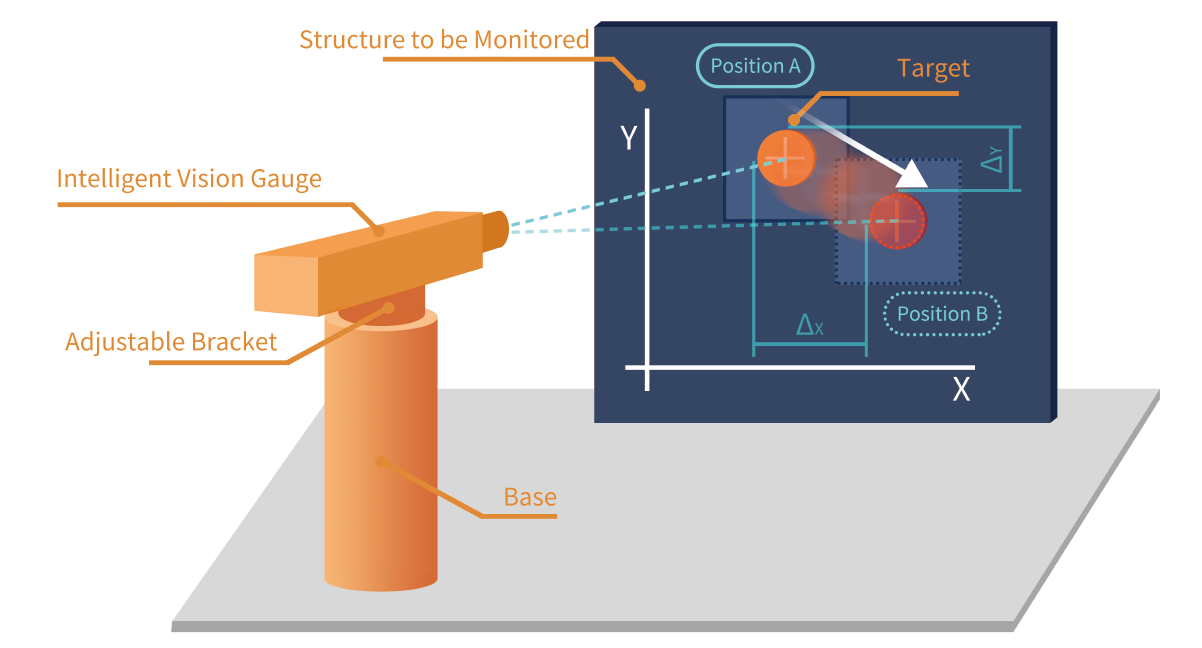

The Intelligent Vision Gauge System is a smart system based on machine vision measurement technology, combined with IoT and intelligent disaster recognition algorithms. It utilizes non-contact measurement and achieves sub-pixel measurement accuracy of structural deformation in water conservancy infrastructure through digital image correlation technology. This system addresses issues such as high investment costs and delayed data in existing dam deformation monitoring technologies, the inability to monitor real-time displacement of dam bodies, and the inability to meet the accuracy requirements of reservoir dam monitoring standards.

The system is composed of a Machine Vision Intelligent Measuring Instrument, a camera lens, a Target, a Local Debugging APP, and the TOEHOLD sensing cloud structure health monitoring management platform.

The Intelligent Vision Gauge contains an embedded computing module that processes images of targets, corrects target displacements, and improves the accuracy of structural displacement monitoring. It also utilizes dynamic local windowing algorithms to solve large computational volume problems, allowing all monitoring data to be processed and computed locally within the embedded computing module.

The gauge can simultaneously measure horizontal and vertical two-dimensional displacements, enabling a single monitoring device to monitor multiple targets, simplifying instrument deployment at the site and reducing monitoring costs.

▋Monitoring Project for a Reservoir Dam

The dam of this reservoir is a concrete face rockfill dam, with a length of 381 meters. The project commenced in August 2006 and was essentially completed by September 2011. To ensure the safe operation of the reservoir, an intelligent vision gauge system is used to monitor surface displacement on the dam crest.

Since the installation, the on-site data has remained stable, with vertical settlement and horizontal deformation not exceeding 3mm.

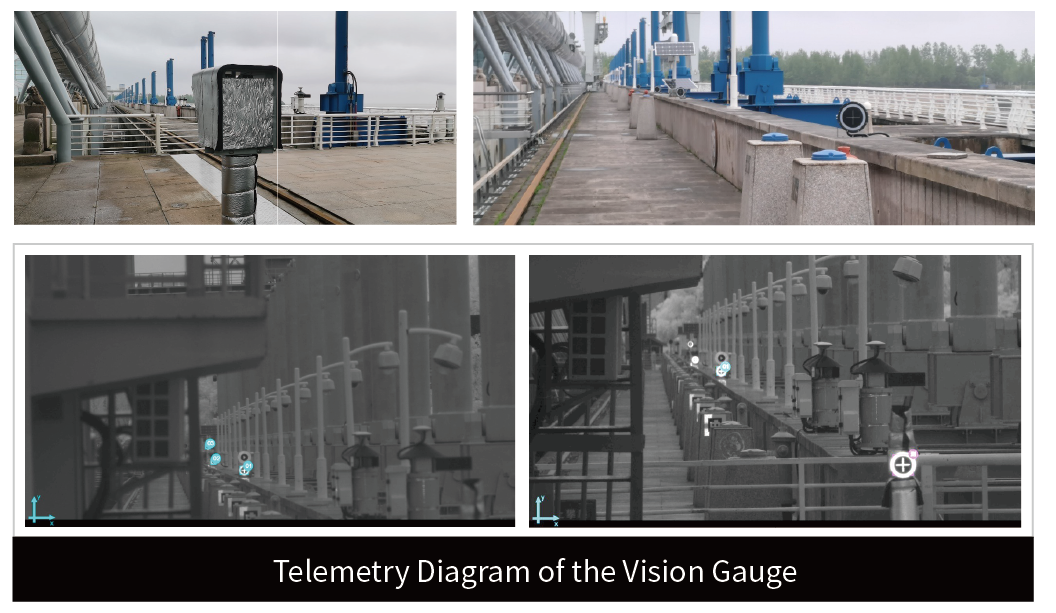

▋Monitoring Project for a Water Gate

The sluice gate is the largest inland river mouth gate in China and is located in an area with complex hydrogeological conditions, particularly affected by tides. It requires real-time and precise measurement of the gate's deformation. To ensure the safety of the gate, several intelligent vision gauges are used to simultaneously monitor the horizontal and vertical displacements of the gate.

Monitoring data shows that the deformation patterns of all measurement points highly correlate with tidal variations. Through high-frequency continuous monitoring, the relationship between the gate displacement and tidal changes was determined for the first time, providing important insights for analyzing the health status of the sluice gate.

© Toehold Engineering Technology Co., Ltd.Shanghai