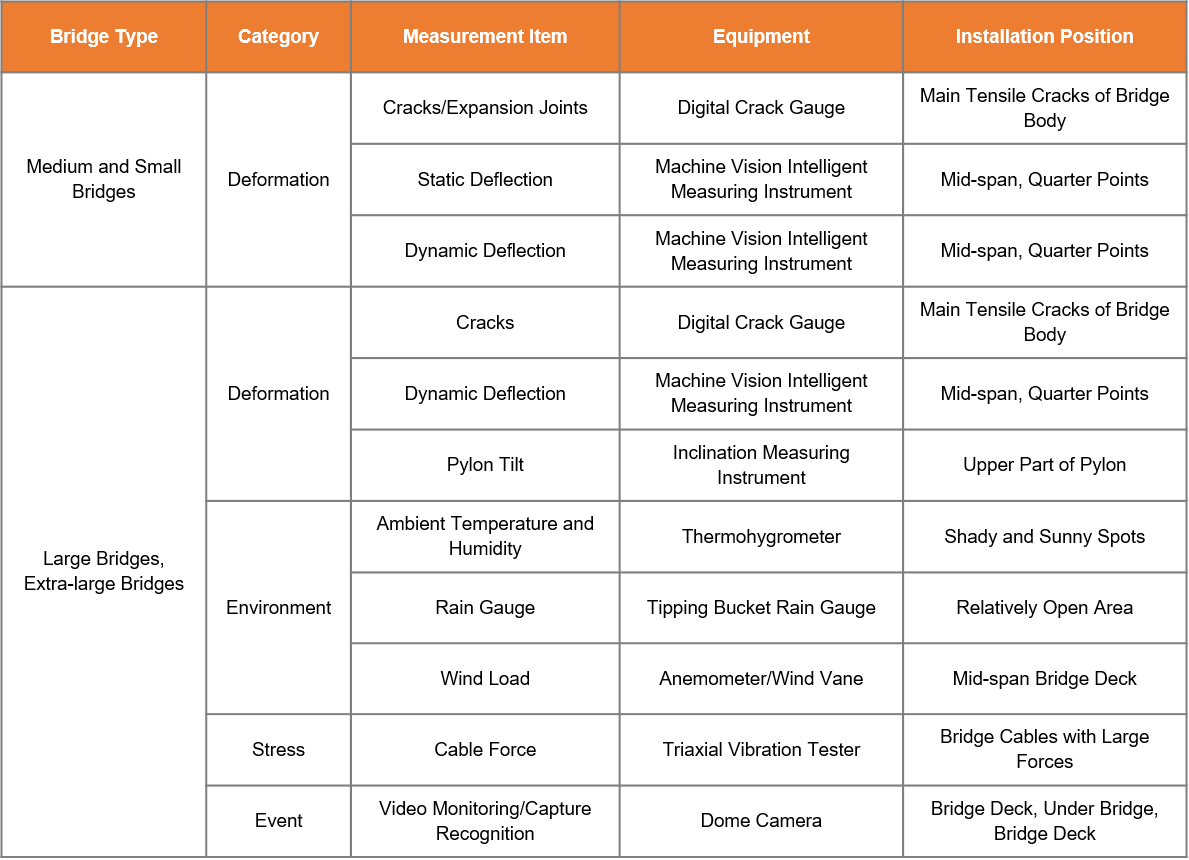

Bridge structure monitoring should prioritize displacement monitoring over force monitoring, as displacement measurement offers the advantages of precision and analytical capability, providing a more intuitive reflection of the bridge's health compared to stress measurement.

Displacement measurement includes both static displacement and dynamic deflection measurement. Static displacement reflects the overall variation of the bridge, while dynamic deflection not only indicates the deformation trend but also directly reflects the extent of damage to the bridge.

Cracks in bridges reduce the effective cross-sectional height of the beam, leading to increased deflection, which in turn accelerates crack development.

Therefore, crack and deflection monitoring are the two primary measurements for medium-sized bridges.

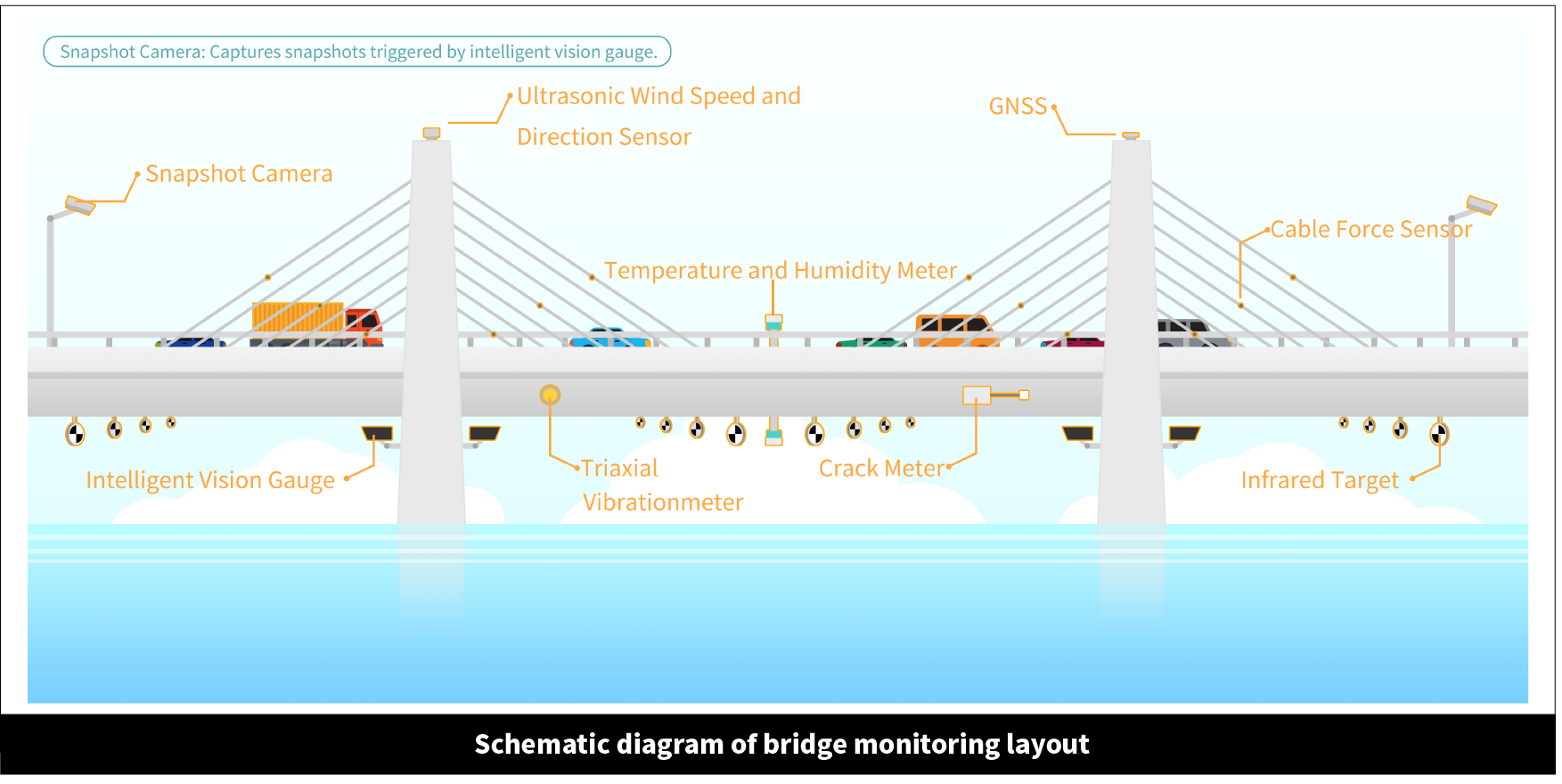

For large and super-large bridges, in addition to crack and deflection monitoring, it's essential to monitor tower inclination, cable forces, wind speed and direction, rainfall, environmental temperature and humidity, as well as traffic flow.

▋A Bridge Group Monitoring Project

This project is a demonstration project for bridge health monitoring. This bridge group that includes cable-stayed arch bridges, reinforced concrete hollow slabs, and other types. These bridges face challenges such as long operational periods, high traffic volumes, and severe overloading. To ensure the safety of daily travel for the public and improve bridge maintenance levels, health monitoring has been initiated for nine major bridges within the group. Based on monitoring results, assessments are made regarding the load and structural health conditions of the bridges.

Taking into account the actual conditions of the bridge group and the structural characteristics of each bridge, a monitoring plan has been designed primarily focusing on dynamic deflection monitoring, combined with snapshot linkage technology and automated health monitoring technology. Key monitoring items include main beam deflection, overloading snapshots, as well as auxiliary monitoring of stress-strain, structural temperature, and environmental temperature-humidity conditions.

Dynamic deflection monitoring points are mainly located at mid-span positions of the main span, placed at the bottom of the beam, with 4-8 monitoring points per section. Overloading snapshots are positioned at corresponding locations on the bridge pedestrian walkway and also capture overloading snapshots for all lanes.

On July 5th, 2021, at 14:54:08, an alarm for mid-span deflection was detected by the machine vision intelligent measurement instrument. Subsequently, the upper snapshot camera was activated. The video footage captured a car passing over the bridge at that moment, exceeding the load limit. The system successfully captured a snapshot of the license plate and identified the vehicle.

▋A Bridge Monitoring Project

The monitored bridge is a central-supporting steel tube concrete basket arch bridge with a main span of 336 meters. The main arch ribs adopt a spatial variable-section truss steel tube concrete composite system, with the main arch axis using a catenary line profile. The two arch ribs tilt inward towards the bridge axis in the vertical plane to form a basket shape. The arch ribs are composed of equal-width variable-height rectangular section steel tube concrete truss structures.

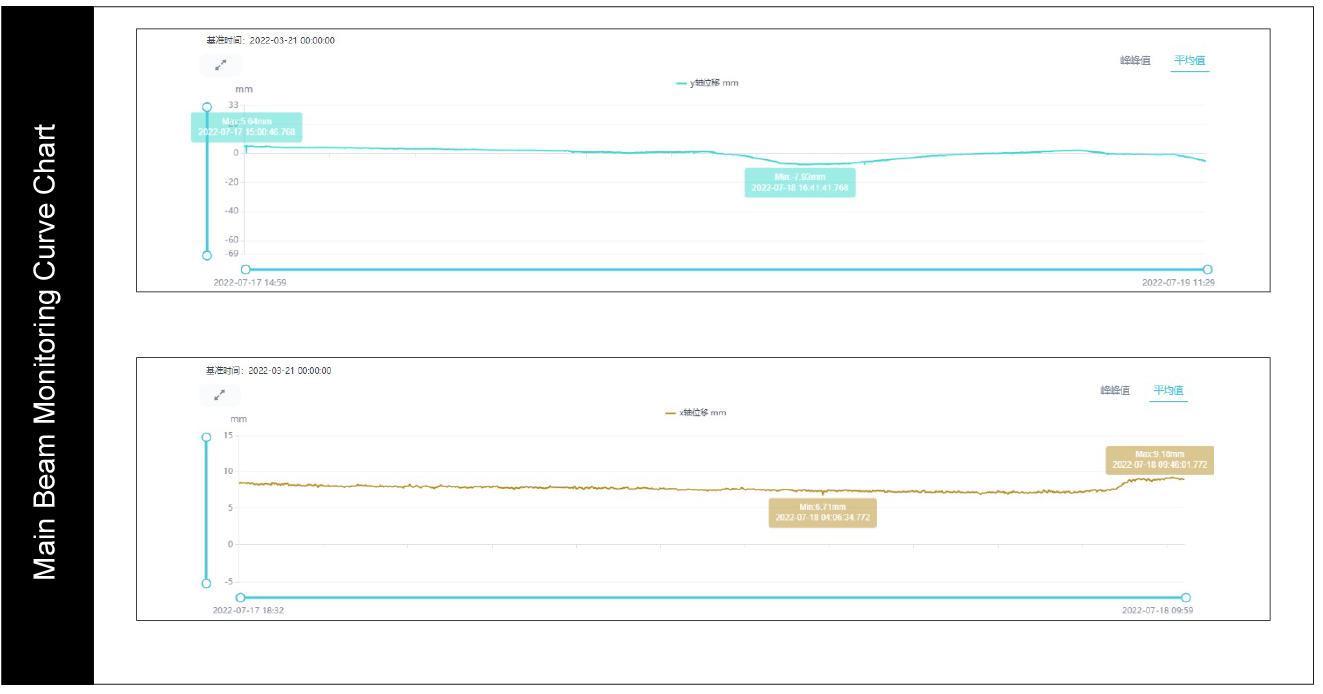

The bridge monitoring project is one of 11 major bridge structure health monitoring points arranged nationwide by the Ministry of Transport. During the project construction period, a machine vision intelligent measurement system was used to monitor the deflection and horizontal displacement of the bridge.

Since the monitoring system was installed and put into operation, the equipment has operated stably. It has performed high-precision measurement of the bridge main girder deflection, and the data indicates that there is no significant excessive deformation. The bridge structure is generally in a healthy state.

© Toehold Engineering Technology Co., Ltd.Shanghai