Prestressed tensioning is a critical construction method performed before concrete pouring, where steel reinforcement is pre-tensioned to optimize the stress distribution within reinforced concrete structures during their service life. The automated control of prestressed tensioning significantly enhances both the quality and efficiency of construction in prestressed reinforced concrete projects.

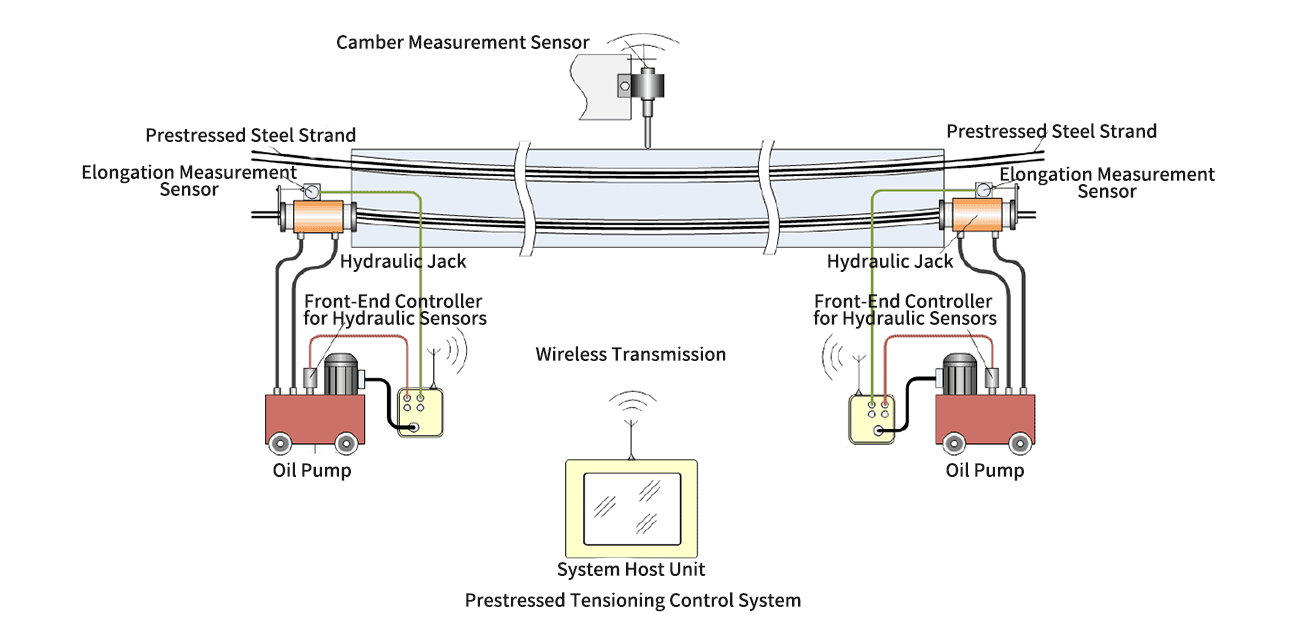

The Program-Controlled Prestressed Tensioning System is an automated construction system that employs a CNC hydraulic system for prestressed tensioning operations. It consists of a program-controlled host unit and field operation units. The field operation units include measurement and control circuitry, hydraulic pumps, jacking equipment, sensors, and other components.

System Schematic Diagram

The host unit comprises an industrial panel computer and a dedicated program-controlled software system, capable of monitoring and controlling multiple numerically controlled oil pumps via wireless signals. Following preset tensioning procedures and corresponding parameters, the host unit directs the operation of one or more numerically controlled oil pumps. It continuously calculates control commands based on monitoring data fed back from these pumps, enabling precise and ongoing regulation.

The numerically controlled oil pumps monitor key data points such as the jack's working tension and the elongation (or retraction) of the steel strands. This data is transmitted in real-time to the host unit, which subsequently sends back control commands. Based on these instructions, the pumps dynamically adjust the inverter's operating parameters. This allows for highly precise real-time regulation of the oil pump motor's speed, ensuring accurate control over the tensioning force and loading rate.

Software Interface

The system hardware comprises an industrial-grade panel computer and numerically controlled oil pumps. The industrial panel computer is equipped with a program-controlled software system, featuring real-time display of multi-front-end tensioning data, comprehensive recording of the entire tensioning process, and robust error tolerance and correction capabilities. The numerically controlled pump stations offer flexible compatibility with various jack models, while the measurement system can be expanded to meet the requirements of different construction methodologies.

The D-Type represents the fully automatic flagship model.Utilizing two oil pumps, it can simultaneously drive four hydraulic jacks, enabling the concurrent tensioning of two steel strands.The entire process is executed through one-touch operation, automatically completing the full prestressed tensioning procedure for both strands.

We provide comprehensive technical support services for both software and hardware operations and maintenance. Our technical team consists of civil engineers, hardware engineers, and software engineers, equipped with the capability to perform customized development for both software and hardware.

© Toehold Engineering Technology Co., Ltd.Shanghai