In modern construction methodologies, there exists a process for transferring the load-bearing system of structures. This involves shifting the existing static loads onto temporary support systems, and then transferring the loads back from the support system to the permanent structure after its construction is completed. Examples include bridge pier replacement projects and the pouring of large-span concrete beams and slabs. From the perspective of the safety and feasibility of this method, this temporary support system places high demands on the synchronization of axial forces at each support, displacement synchronization, and the dynamic synchronization during loading and unloading.

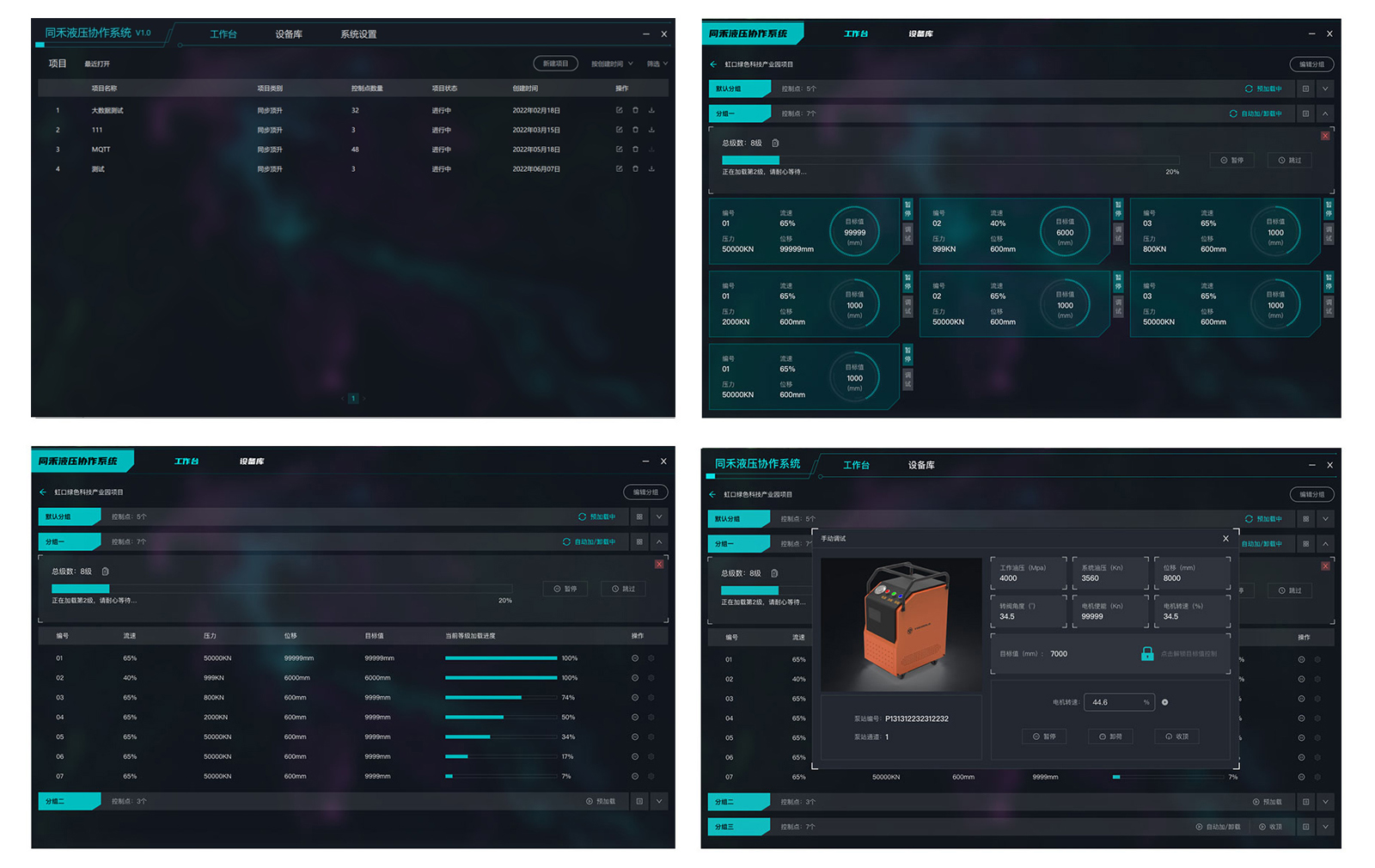

The synchronous lifting solution employs a self-developed, numerically controlled hydraulic system as hardware, complemented by axial force synchronization control software to achieve fully automated adjustment throughout the loading/unloading process. Augmented with automated monitoring components, it provides real-time monitoring of each step in the synchronous lifting construction sequence, further ensuring the safety of the construction process.

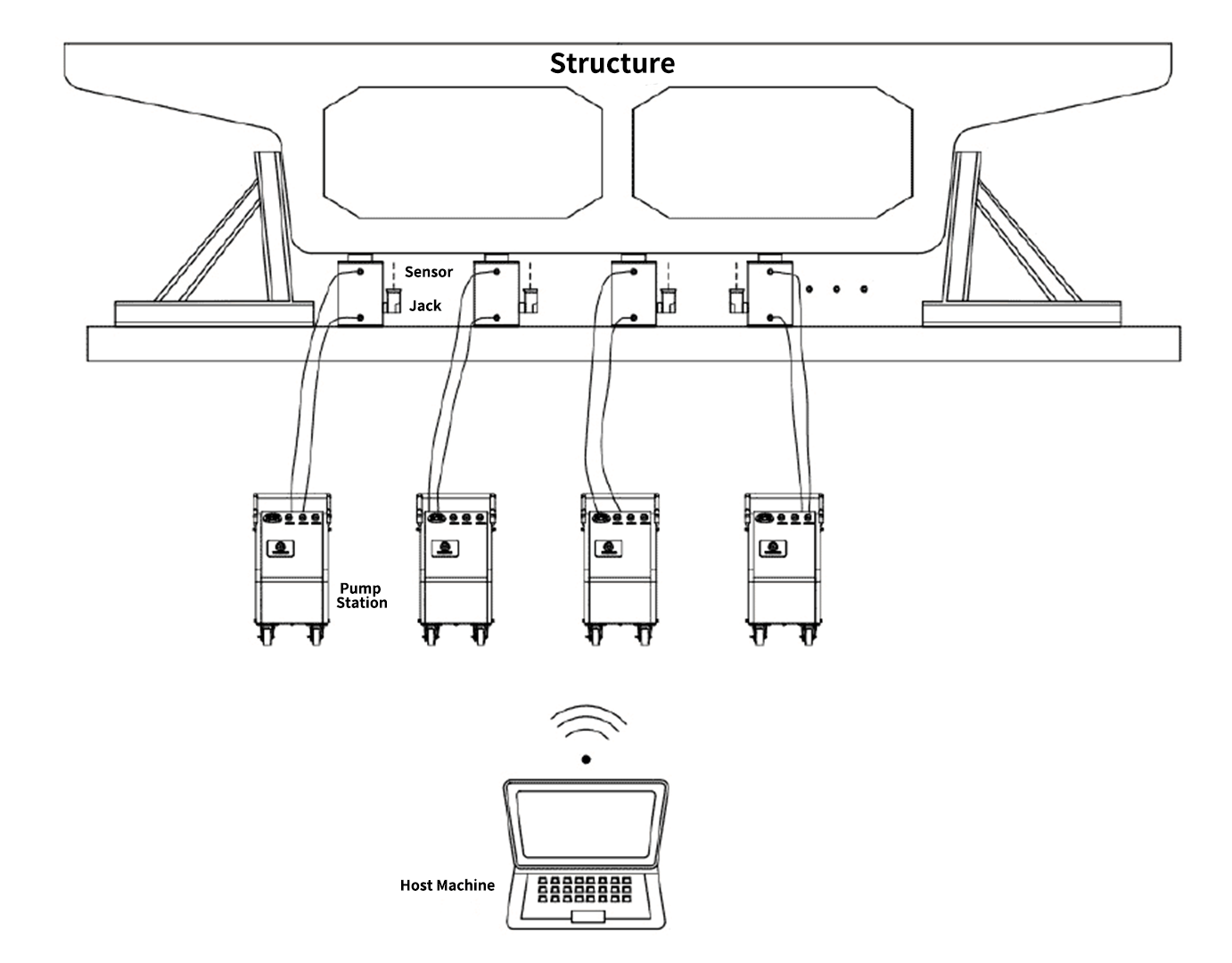

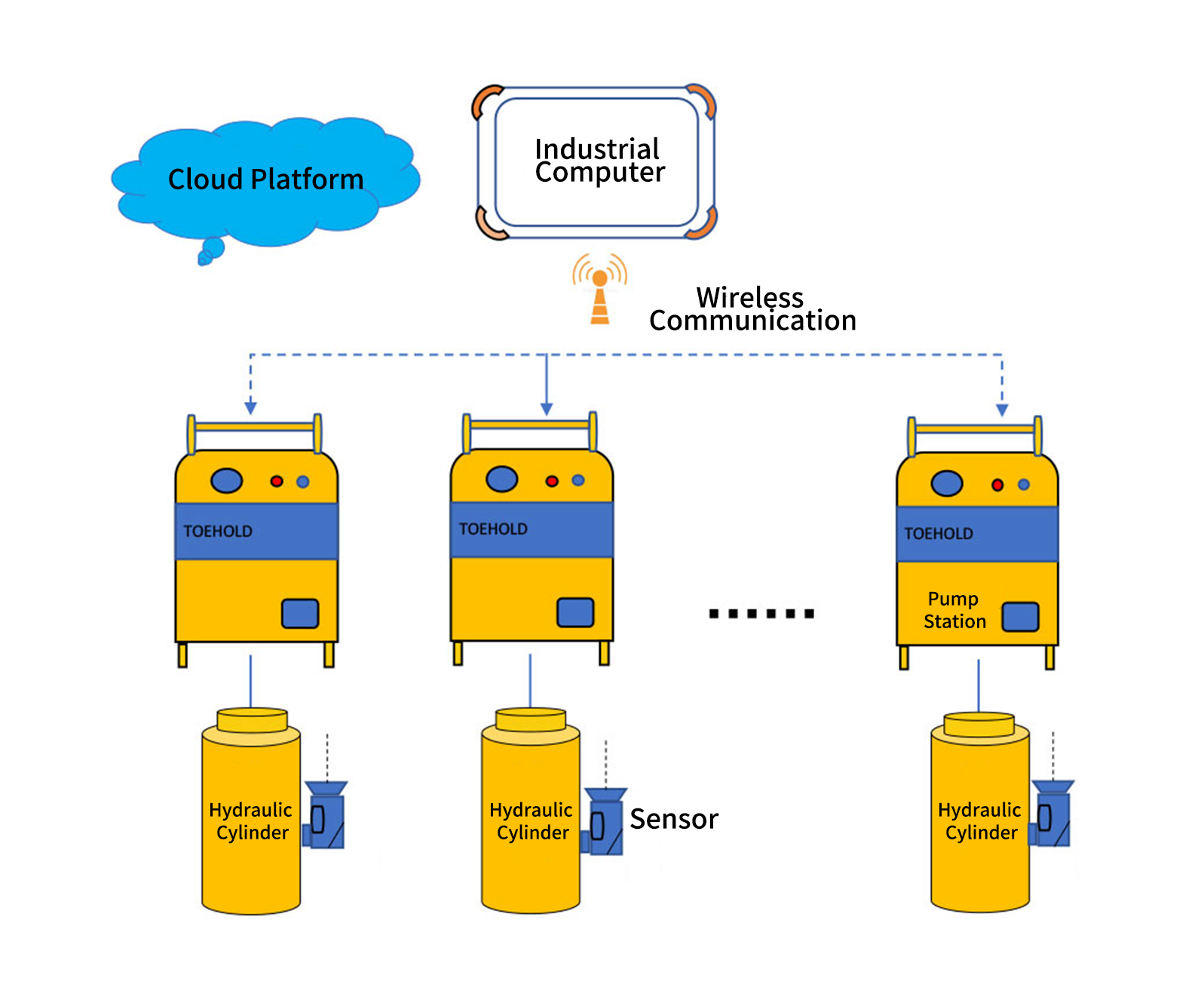

The synchronous lifting system consists of master control software, an industrial panel computer (host unit), numerically controlled pump stations, sensors, and hydraulic cylinders. The master control software serves as the system's command center, operating on the industrial panel computer. It responds to user requirements by sending control commands to the numerically controlled pump stations, thereby driving the operation of the hydraulic cylinders, while simultaneously receiving real-time pressure and displacement data collected by the sensors. The master control software processes and analyzes this feedback data. Finally, based on the data processing results, it issues further adjustments to the pump stations' actions, thereby forming a dynamic closed-loop control system.

The system primarily consists of master control software, an industrial panel computer (host unit), numerically controlled pump stations, sensors, hydraulic cylinders, and cloud data services. The master control software, operating on the industrial panel computer, can manage and control up to 200 numerically controlled pump stations. Utilizing CAT1 wireless communication, it achieves high concurrent response rates, synchronization, and exceptional real-time performance. Construction data is promptly backed up to the cloud platform, which also enables remote control functionality.

We provide comprehensive technical support services spanning from construction planning to post-construction data analysis. Our technical team comprises civil engineers, hardware engineers, and software engineers. This multidisciplinary composition enables us to design rational and efficient construction plans tailored to client requirements, while possessing the capability to perform customized development for both software and hardware.

© Toehold Engineering Technology Co., Ltd.Shanghai