Excavation engineering is a primary methodology for urban underground works in China. Under soft soil engineering geological conditions, issues such as stratum disturbance, water and soil loss, and settlement of environmental structures caused by delayed strut installation and loss of strut axial force are particularly pronounced. With the development of urban rail transit systems and underground engineering, the characteristics of "deep, challenging, and risky" associated with subsequent underground construction projects are becoming increasingly significant. Consequently, resolving the environmental impact problems during excavation construction is extremely urgent.

The Strut Force Servo System offers a complete set of safety solutions for pit support. By integrating hydraulic technology, automated monitoring technology and IoT technology, it continuously monitors strut axial force and pit deformation. According to the pit deformation data, the system dynamically adjusts the axial force, safeguarding both the excavation pit and surrounding structures from excessive deformation and stress.

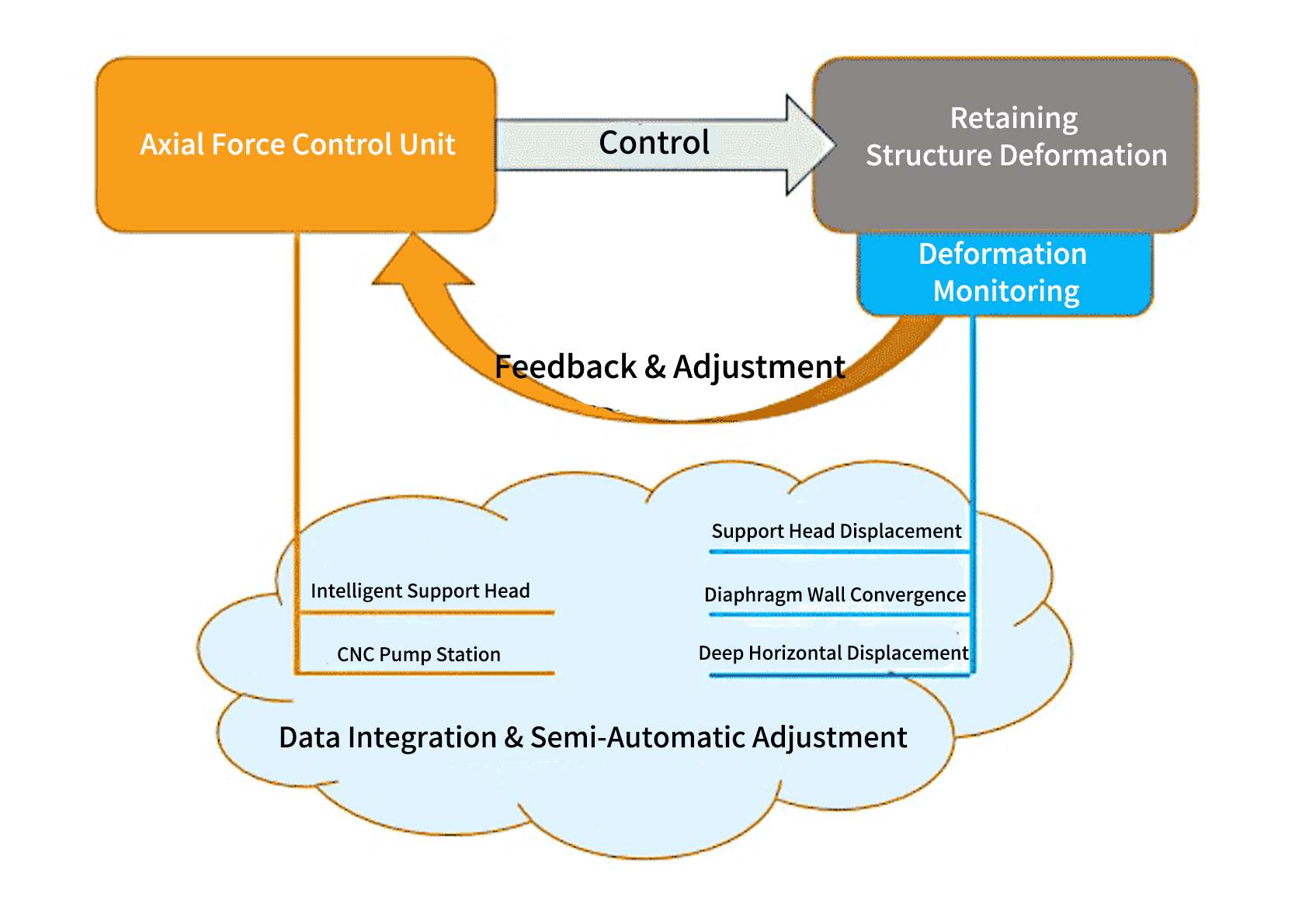

The Strut Axial Force Servo System employs an axial force control unit to actively manage strut axial forces, balancing external soil pressure and thereby controlling deformation of the retaining structure. Simultaneously, a deformation monitoring unit records the displacement of the retaining structure, providing critical data for the axial force control unit to make precise adjustments. The entire system operates through highly automated site software that enables semi-automatic regulation, while transmitting all data to the Tonggan Cloud Platform for remote monitoring and control.

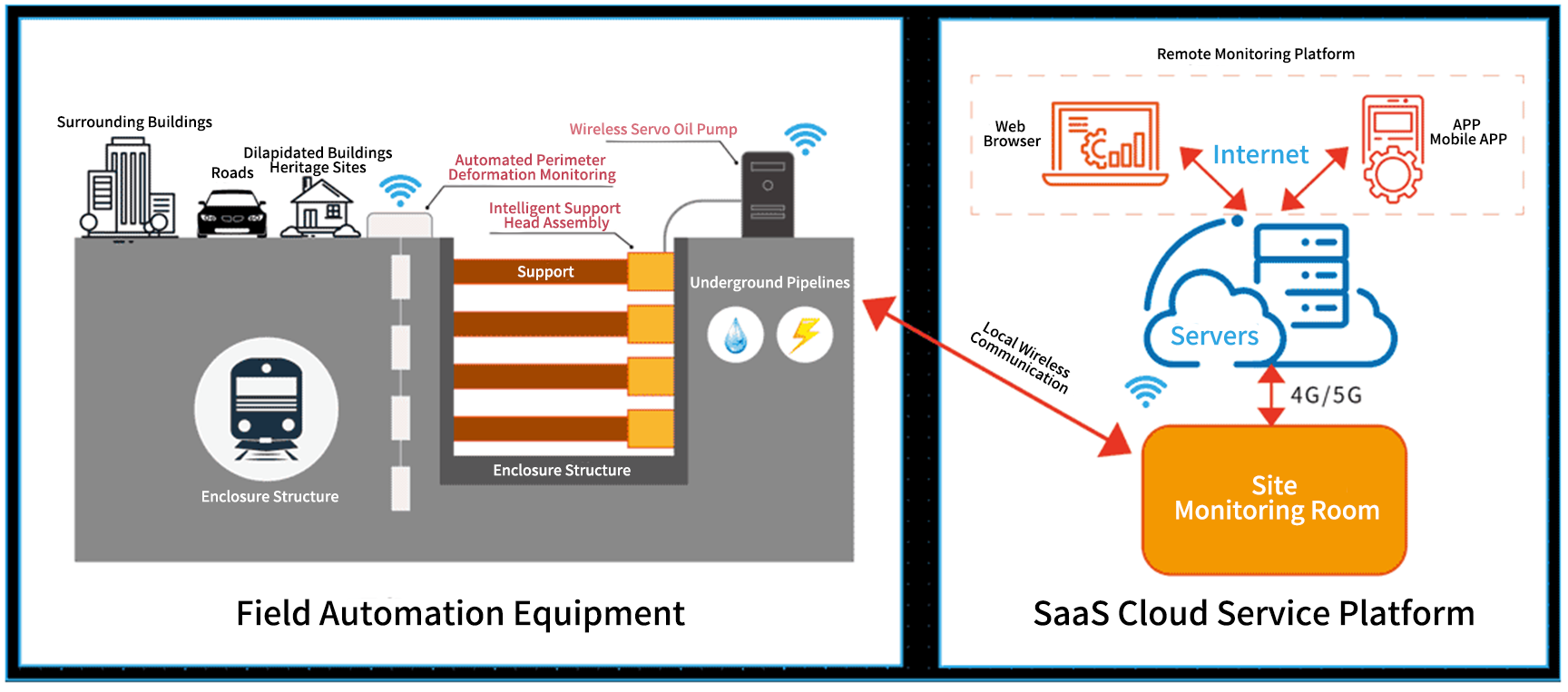

The Servo-Controlled Strut Axial Force System comprises field automation equipment and the Tonggan Cloud Service Platform.

Field Automation Equipment: The intelligent support head assembly can apply axial force. Coordinated with the wireless servo pump station, it enables precise adjustment of the axial force applied by each support head. Laser convergence meters deployed on-site monitor the relative convergence deformation of the retaining structure in real-time and transmit the data back to the host computer in the field control room. The host computer processes the axial force, temperature, and deformation data in real-time, enabling 24-hour intelligent servo control of the field equipment.

Multi-Project Remote Management

Provides Real-Time Monitoring Curves for Axial Force, Temperature, and Head Travel

Table View

Event Log

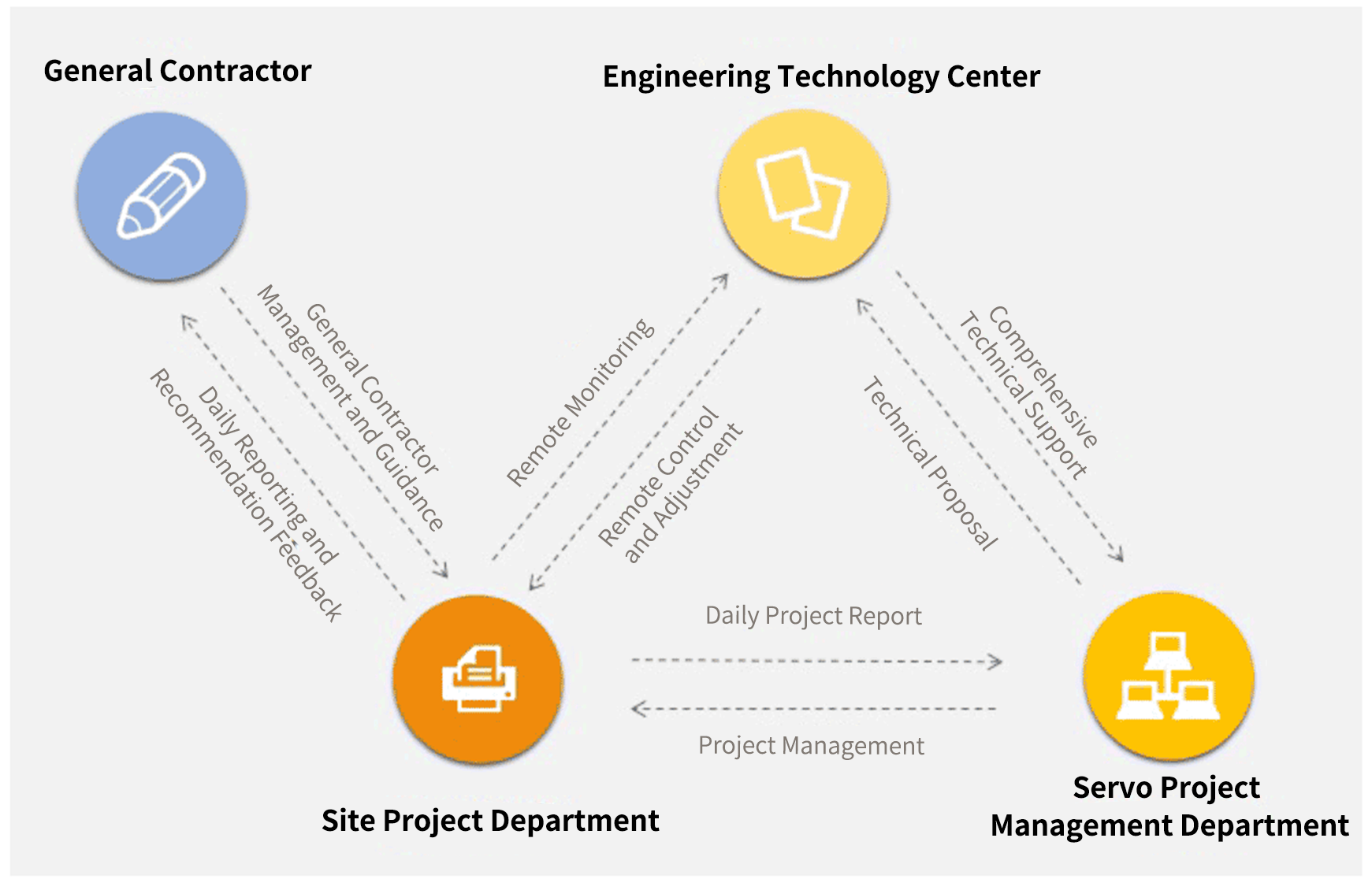

The Strut Axial Force Servo System not only provides customers with safe and reliable equipment but also delivers comprehensive project lifecycle management and technical support services throughout the entire implementation process.

© Toehold Engineering Technology Co., Ltd.Shanghai