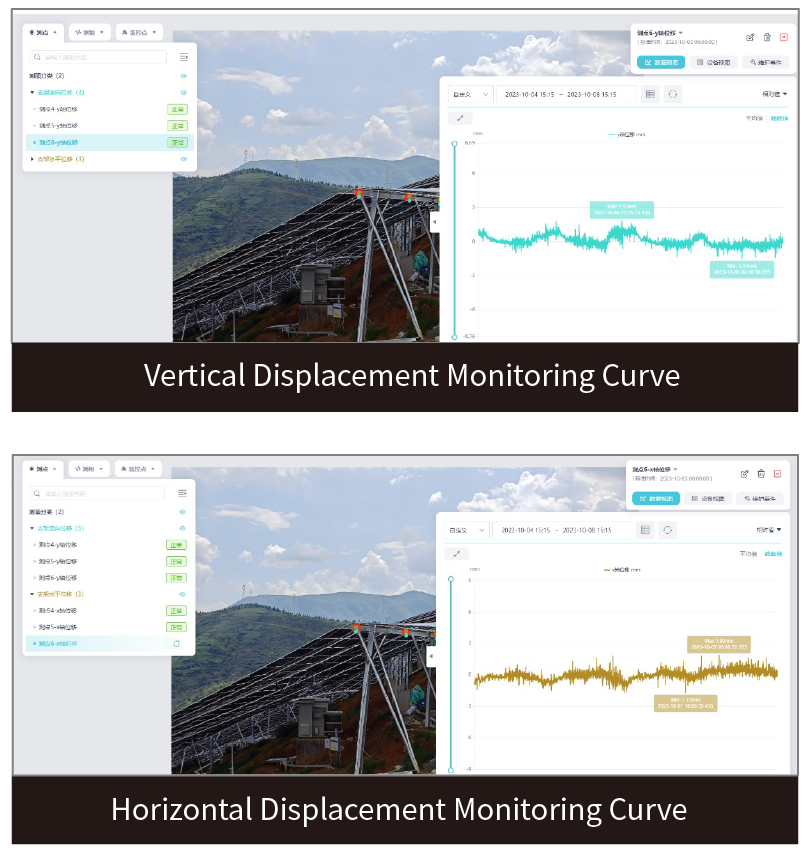

▊ Monitoring of Flexible Supports in Photovoltaic Power Stations

The module supports of this photovoltaic power station adopt a three-cable structure flexible support, which is installed with a fixed inclination angle and following the terrain slope. The total length of a single set of flexible supports ranges from 180m to 400m, with a height difference of 60m to 140m. The overall slope is between 19° and 28°, and the local slope exceeds 35°. The single-span range is mainly 30m to 60m, and the column height range is mainly 2.5m to 5m. The nominal diameter of the cable strand is 17.8mm.

For this project, a monitoring design is carried out for the existing flexible support structures of the power station. Monitoring points for tracking structural changes are arranged at positions with high stress, large deformation, vulnerability, and potential impacts on the safety and durability of key components and the overall structure. This enables dynamic monitoring of the operating status of the existing flexible supports, helps grasp the operating rules, provides basic data for relevant units, and supports scientific research experiments and design verification.

To establish the relationship between wind loads and structural responses, if total stations are used for manual observation of support displacement, the monitoring frequency is too low to meet requirements. When GNSS monitoring technology is adopted, long-term calculation is required to achieve high precision; however, high frequency cannot be achieved while ensuring precision. To meet the monitoring frequency requirements and obtain high-precision monitoring data simultaneously, the project adopts a intelligent vision gauge system for real-time monitoring of flexible support displacement.

Since the equipment has been in operation, the monitoring data has remained stable. Both the vertical displacement and horizontal displacement values are within ±2mm, and the flexible support structure is in an overall stable state.

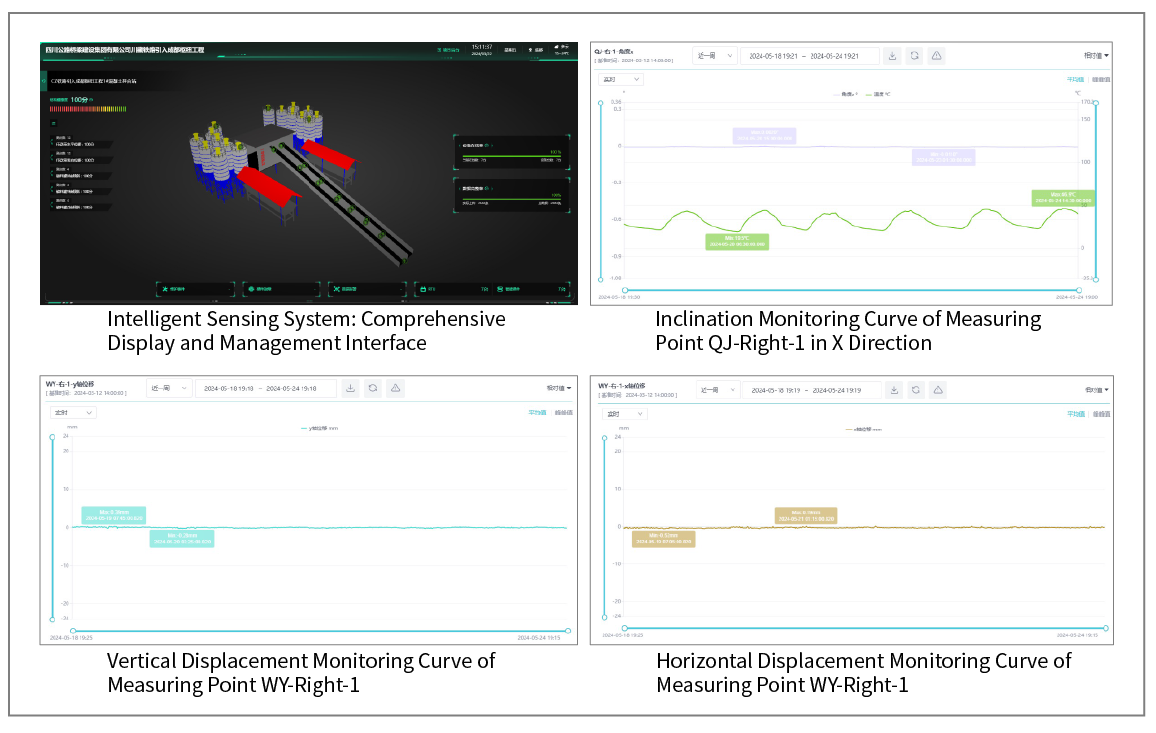

▊ Structural Safety Monitoring of High-Speed Railway Concrete Mixing Plant

As a temporary railway structure, the high-speed railway concrete mixing plant features high height, large dynamic loads, and complex stress conditions. Under load action, the single deformation of the structure is small; however, if the structural deformation approaches the critical value, or under the action of force majeure factors such as geological changes, wind and rain loads, and seismic loads, disaster accidents are likely to occur without timely reinforcement measures. Therefore, it is necessary to conduct real-time monitoring of the horizontal and vertical displacements of the conveyor belt and the inclination of the material storage tank in the high-speed railway concrete mixing plant.

Through the construction of the safety monitoring system, high-precision real-time collection and transmission of safety monitoring data, 3D intelligent display, and full-life cycle statistical analysis of the high-speed railway concrete mixing plant have been realized, achieving the effect of intelligent perception and intelligent management of the structure's safety. Since the equipment was put into operation, the values of each measuring point have remained stable, and no obvious abnormal changes have occurred in the horizontal/vertical displacement of the conveyor belt and the inclination of the material storage tank. The mixing plant facilities are in a healthy operating state.

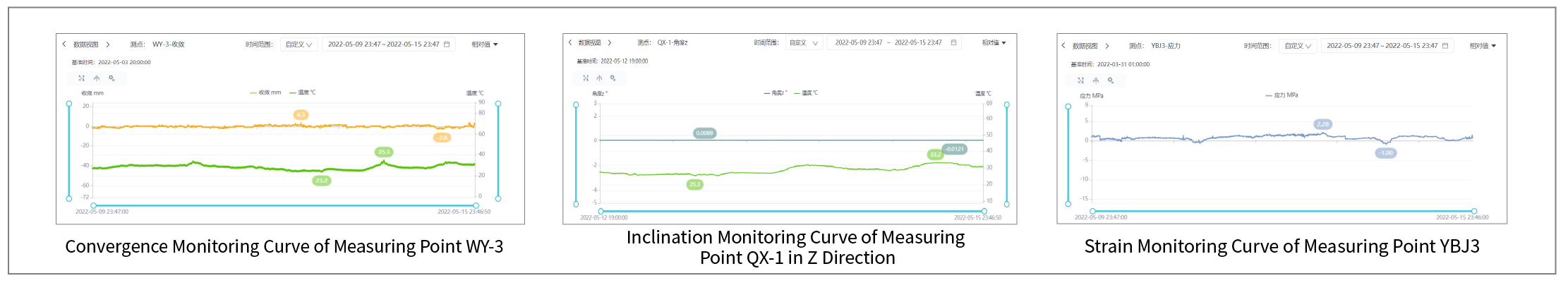

▊ Monitoring of Steel Columns for Ash Hopper Equipment in Power Plant

Due to production needs, this power plant conducts ash cleaning operations on the ash hoppers. The ash hopper columns feature high height, large load, complex structural system and complicated force conditions. During the ash cleaning process, affected by load redistribution, the columns are prone to inclination, displacement and rapid changes in axial force, which may lead to large-scale collapse accidents. Therefore, real-time monitoring of the safety and stability of the columns during the construction period is required.

In this project, 4 inclinometers, 4 laser convergence gauge and 8 string-type surface strain gauges are used to monitor the inclination, displacement and axial force of the columns respectively. Additionally, an acoustic-optical alarm is installed near the monitoring area to provide on-site acoustic and optical alarm assistance.

During the ash cleaning operation of the ash hopper, the values of each measuring point remained stable. No obvious abnormal changes occurred in the convergence, inclination and strain data. Each column showed small deformation and relatively stable force-bearing condition.

© Toehold Engineering Technology Co., Ltd.Shanghai