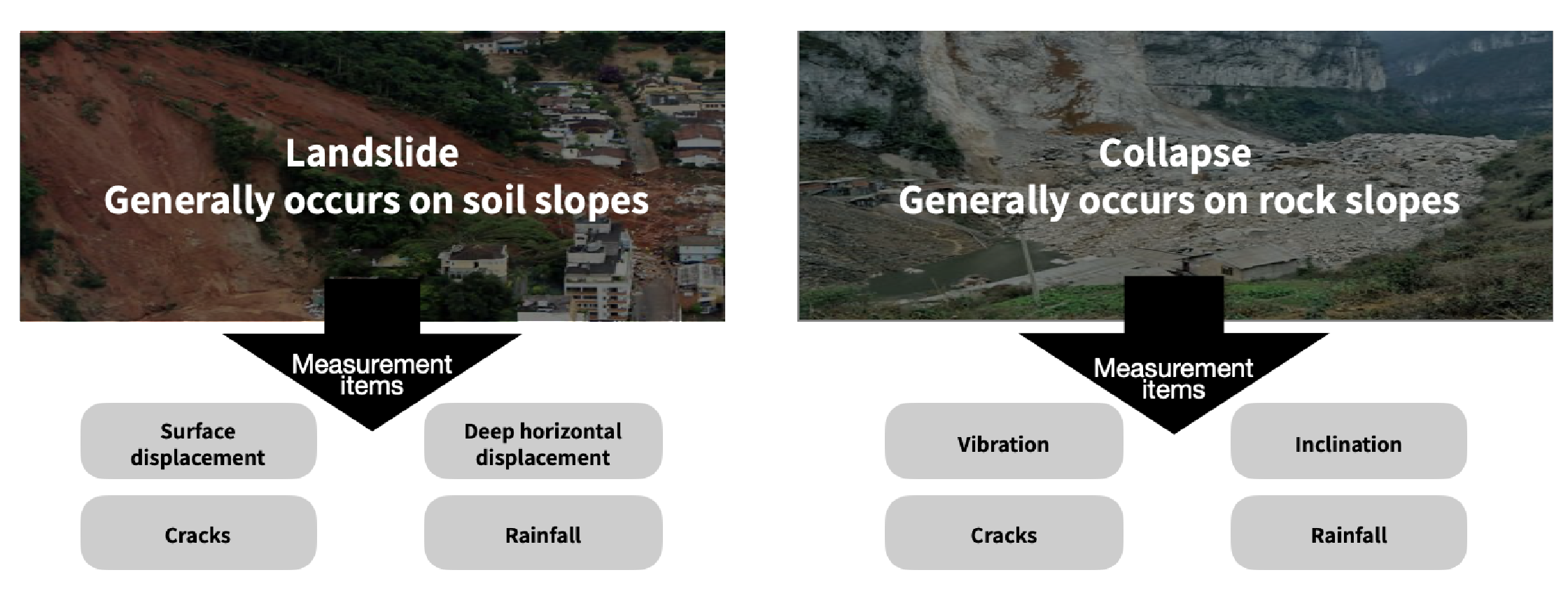

The catastrophic changes of a slope are a process that evolves from slow quantitative changes to qualitative changes. We can use IoT monitoring technology to conduct long-term monitoring of slope deformation. Through big data analysis, we can identify early warning signs of disasters and issue alerts in advance.

A series of intelligent sensors are installed on the monitored slope to collect relevant data on the slope's structural safety. This data is uploaded to the cloud in real time via the network. After being analyzed and calculated by the system, the changing patterns of the slope are identified, enabling early warnings.

▋Intelligent Vision Gauge Using Project

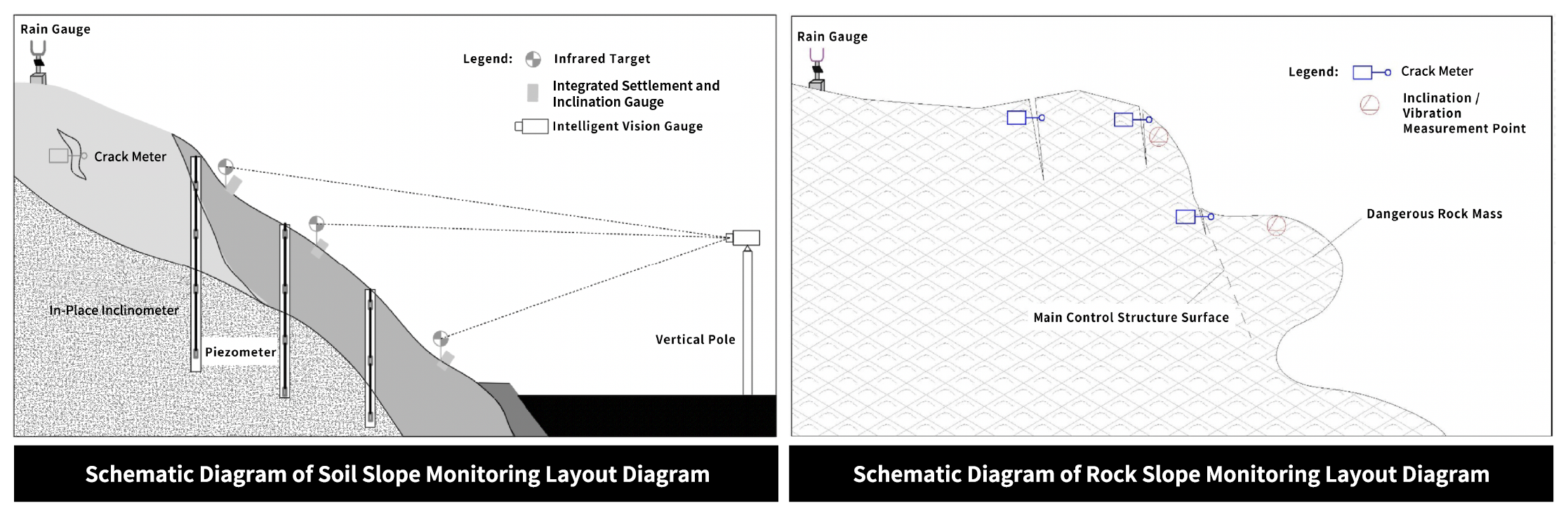

For a highway slope in Zhejiang Province, China, the slope length is 375 meters, and the maximum slope height is 70 meters. The geotechnical properties of the slope mass mainly include eluvial-colluvial soil layers and weathered, loose, and fragmented rock masses. The thickness is greater near the slope toe, generally reaching 11.6–12.1 meters, and gradually decreases from the slope toe upward along the hillside. To grasp the operational status of the slope in real time and ensure traffic safety, automated monitoring is carried out on this slope. According to the structural characteristics of the slope, the main monitoring contents are determined as surface displacement and cracks, which are monitored by Intelligent Vision Gauge and digital crackmeter respectively.

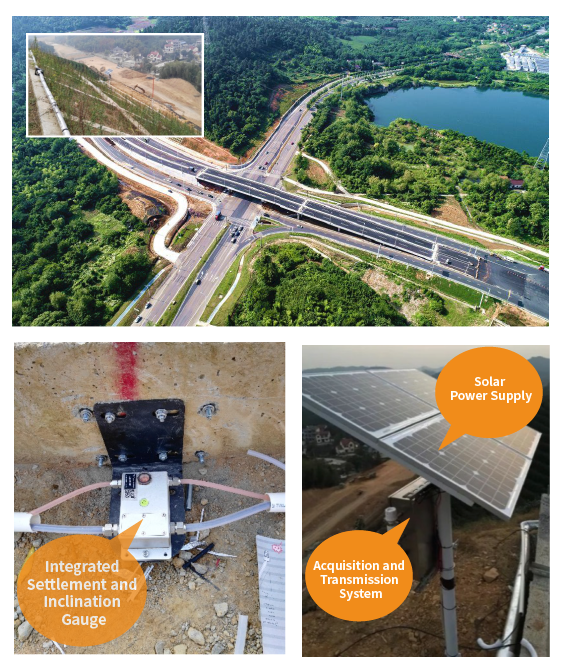

▋Integrated Settlement and Inclination Gauge Using Project

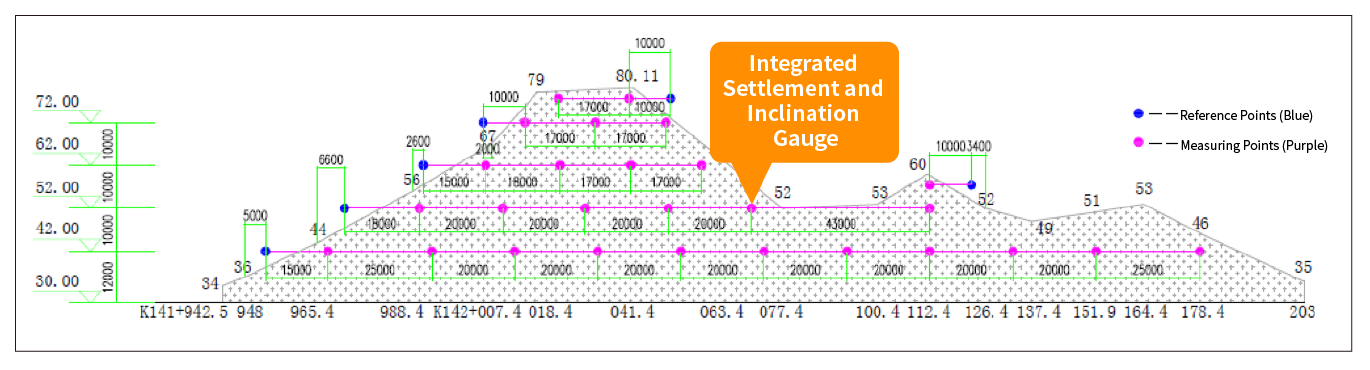

A certain expressway in Zhejiang Province has a total route length of approximately 48 km. Along the route, there are 13 high cutting slopes with an excavation height exceeding 30 m, among which 7 slopes are rated as high-risk in the overall risk assessment. TOEHOLD has implemented automated safety monitoring for these 7 high-risk slopes of the project. The integrated settlement and inclination gauge is used for surface displacement monitoring. One of the slopes has a height of approximately 42 m and a length of about 260 m, with a total of 5 levels. In accordance with the contour layout principle, 5 survey lines and 27 measuring points have been deployed.

At the starting end of each survey line, a relatively stable location is selected to install a reference point, along with the deployment of a solar power supply system and a data acquisition and transmission system. Longitudinally, measuring points are deployed at intervals of no more than 20 meters. All measuring points and reference points are connected using water pipes, air pipes, and cables, and wrapped with thermal insulation materials. After commissioning and setting the sampling frequency, the system enters the operational state.

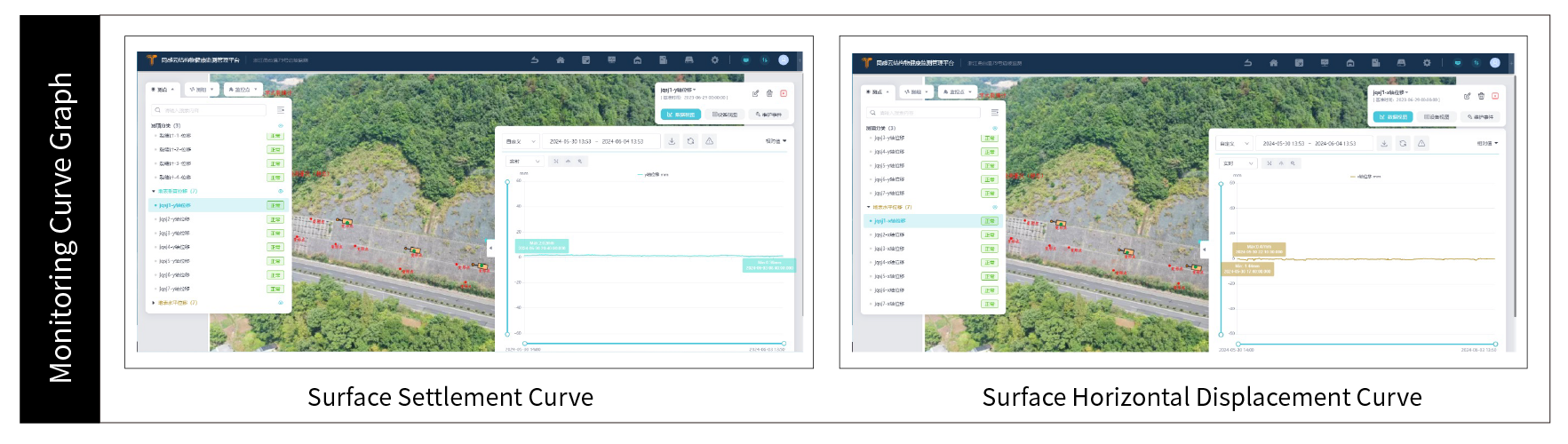

The on-site data acquisition and transmission system transmits data from all measuring points to the cloud, allowing managers to view and manage the data.

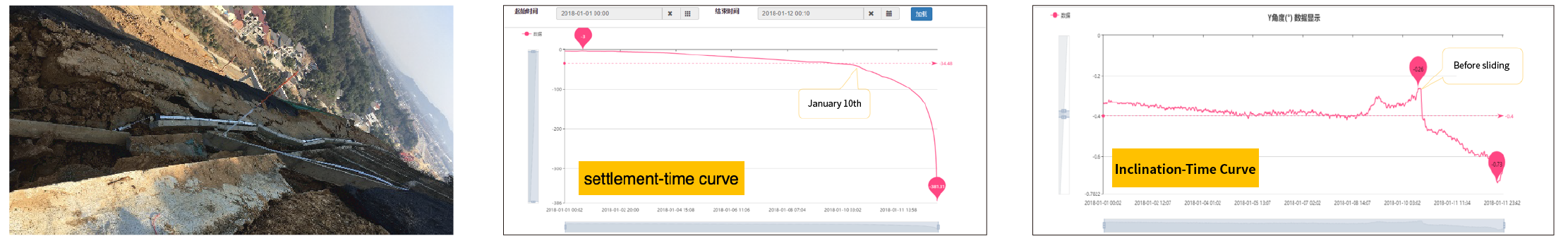

The automated safety monitoring equipment for Slope 7 was fully installed and began monitoring at the end of 2017, and successfully warned of a landslide accident on January 11, 2018.

During this slope collapse incident, the TOEHOLD Sensing Cloud Platform promptly increased the monitoring frequency and early warning level based on data changes. On January 11, an early warning was issued to the construction unit and the owner unit, prompting them to take emergency measures for Slope 7 and evacuate on-site personnel and facilities in a timely manner. Ultimately, this landslide accident did not cause any casualties or property losses.

© Toehold Engineering Technology Co., Ltd.Shanghai