A fully automatic servo system applied in excavation support to control deformation and ensure the safety of both construction and surrounding structures.

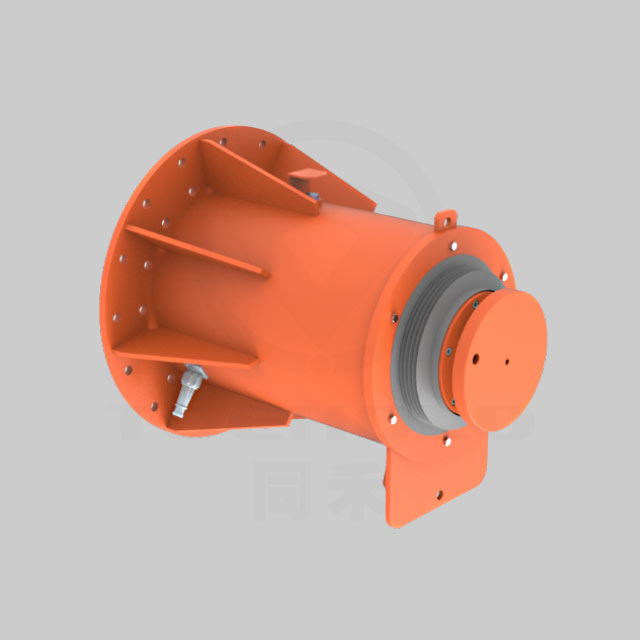

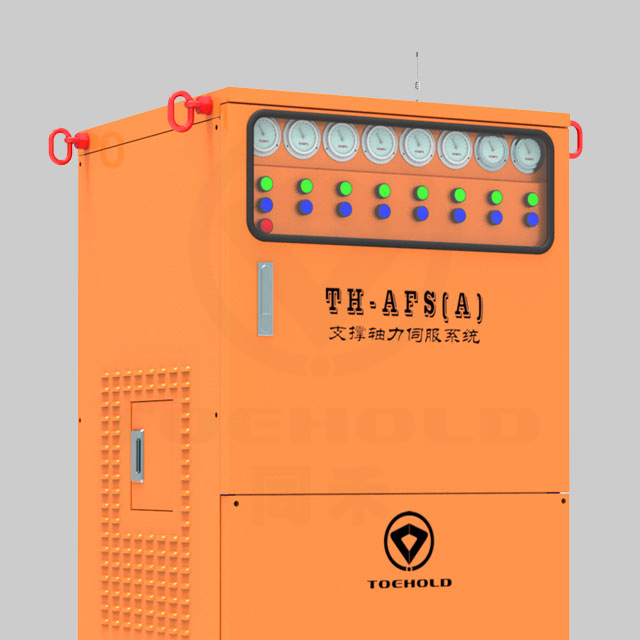

The Strut Force Servo System is a comprehensive safety solution for excavation support. It is designed for projects that require strict control of excavation-induced deformation.The system's key features include 24-hour continuous monitoring, automatic low-pressure compensation, and high-pressure alarms. This multi-layered approach provides all-around safety assurance.

The prestressing tensioning program-control system consists of a program-control host unit and an operation front-end. The operation front-end includes: measurement and control circuits, an oil pump, hydraulic jacks, sensors, and other components. The D-Type is the flagship system, which utilizes a dual-circuit numerically controlled oil pump capable of simultaneously driving four hydraulic jacks to achieve symmetrical tensioning of two steel strands.

The Tension Stress Detector consists of a program-controlled host unit and an operation front-end. The front-end includes measurement and control circuitry, a numerically controlled pump station, a dedicated hydraulic jack, load sensors, and other components. It employs the re-tensioning method principle to test individual steel strands. The system is now widely used in Zhejiang, Yunnan, Guangdong, Guizhou, Anhui, Guangxi, and other provinces.

The synchronous lifting system comprises a host unit, CNC pump stations, hydraulic cylinders, sensors, application software, and other components. It can be flexibly configured according to project requirements to perform installation and correction adjustment work on large structures, including pushing, lifting, raising, and rotating. The system offers high precision, minimal synchronization error, intelligent operation, a high degree of automation, and a distributed structure that ensures safety and reliability.

© Toehold Engineering Technology Co., Ltd.Shanghai